GEODETIC MEASUREMENTS AND MAPPING FOR THE OPENING OF THE OLD BARITE QUARRY IN SUCEAVA COUNTY, ROMANIA: AN EXPLORATION BASED ON DRONE LIDAR SCANNING

Introduction:

The Old Barite Quarry in Suceava county, Romania, offers a fascinating opportunity for exploration and analysis. This article describes the project, highlighting the involvement of Simion Bruma, a UAV pilot from BDS Topografie SRL, and the use of the latest model of the TOPODRONE LiDAR 200+, equipped with the Hesai XT32M2X sensor and a high-performance GNSS-based inertial navigation system. The project also included the collection of ground control points (GCPs) using GNSS technology to validate the data acquired with the LiDAR sensor.

Fig. 1. Simion Bruma, from BDS Topografie SRL.

Description of the area:

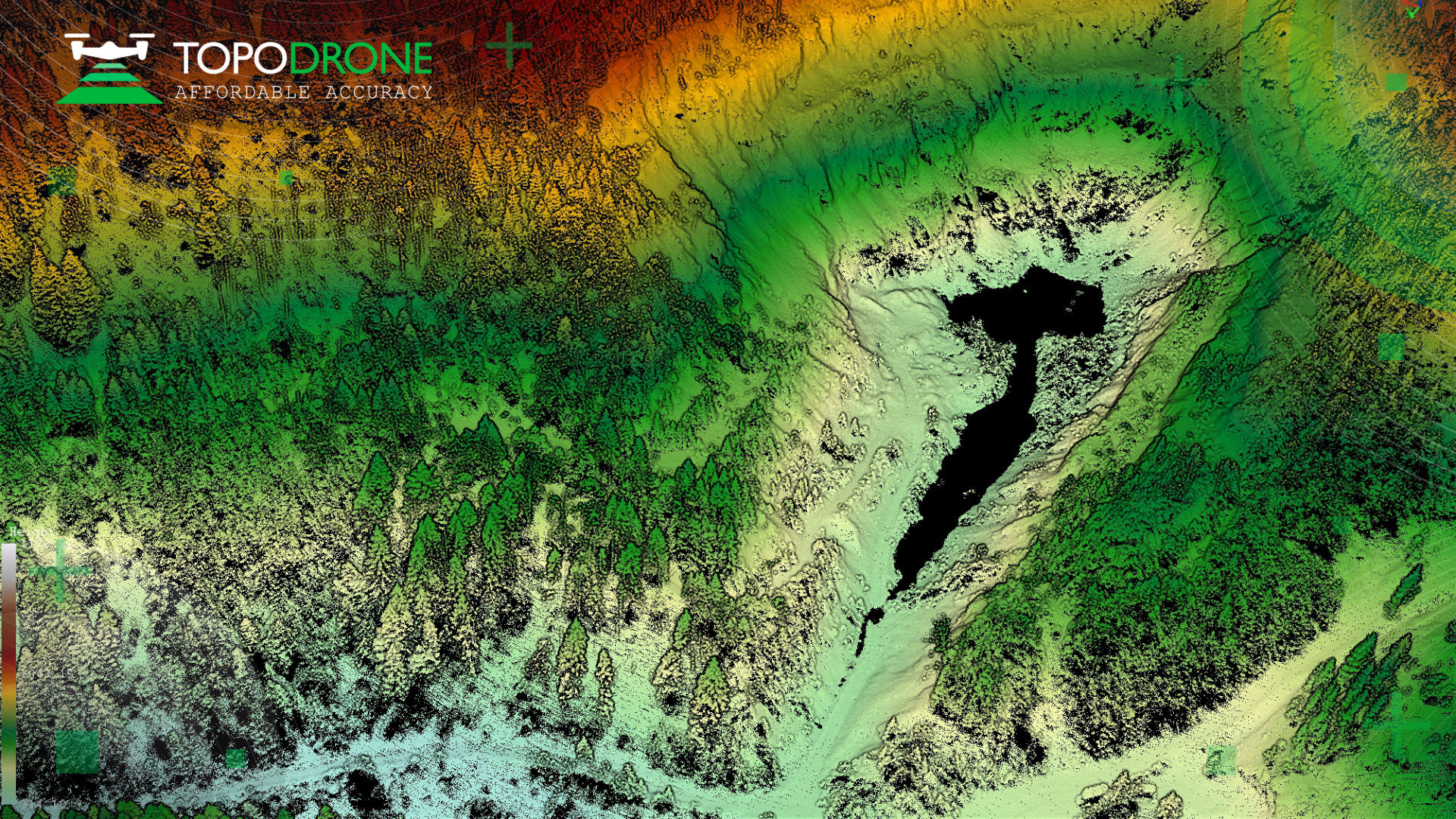

Fig. 2. Mountain forest area of The Old Barite Quarry, located in Suceava, Romania.

The Old Barite Quarry, situated in Suceava, Romania, provides a unique setting for investigation and potential development. The quarry covers an area of 100 hectares, including a mining area of 40 hectares. With altitudes ranging from a minimum of 914 meters to a maximum of 1172 meters, the region has significant elevation differences, adding to the geological significance of this site.

Field work, flights and altitude:

Fig. 3. TOPODRONE LiDAR 200+ installed on board the DJI M200 drone.

To effectively collect comprehensive data of the Old Barite Quarry, Simion Bruma carried out a single flight using the DJI M210 + TOPODRONE LiDAR 200+. The TOPODRONE LiDAR 200+ system, equipped with a high performance GNSS-based inertial navigation system, enabled the acquisition of up to 1,920,000 points per second with a 360° field of view and up to 3 cm x,y,z accuracy. The low weight of the LiDAR system (700 grams) provides a significant improvement in flight time and efficiency, even on board an old model DJI M200 drone.

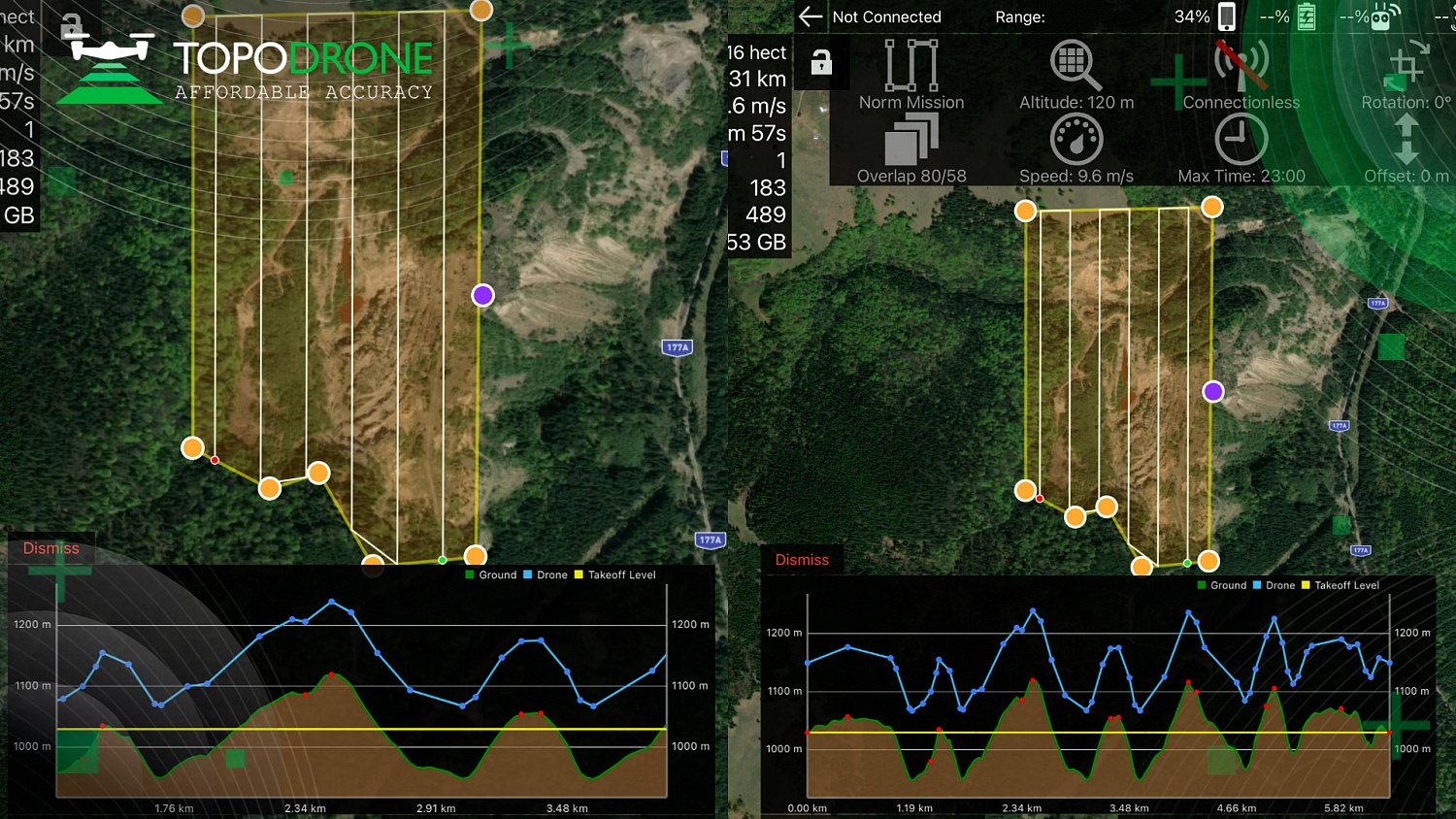

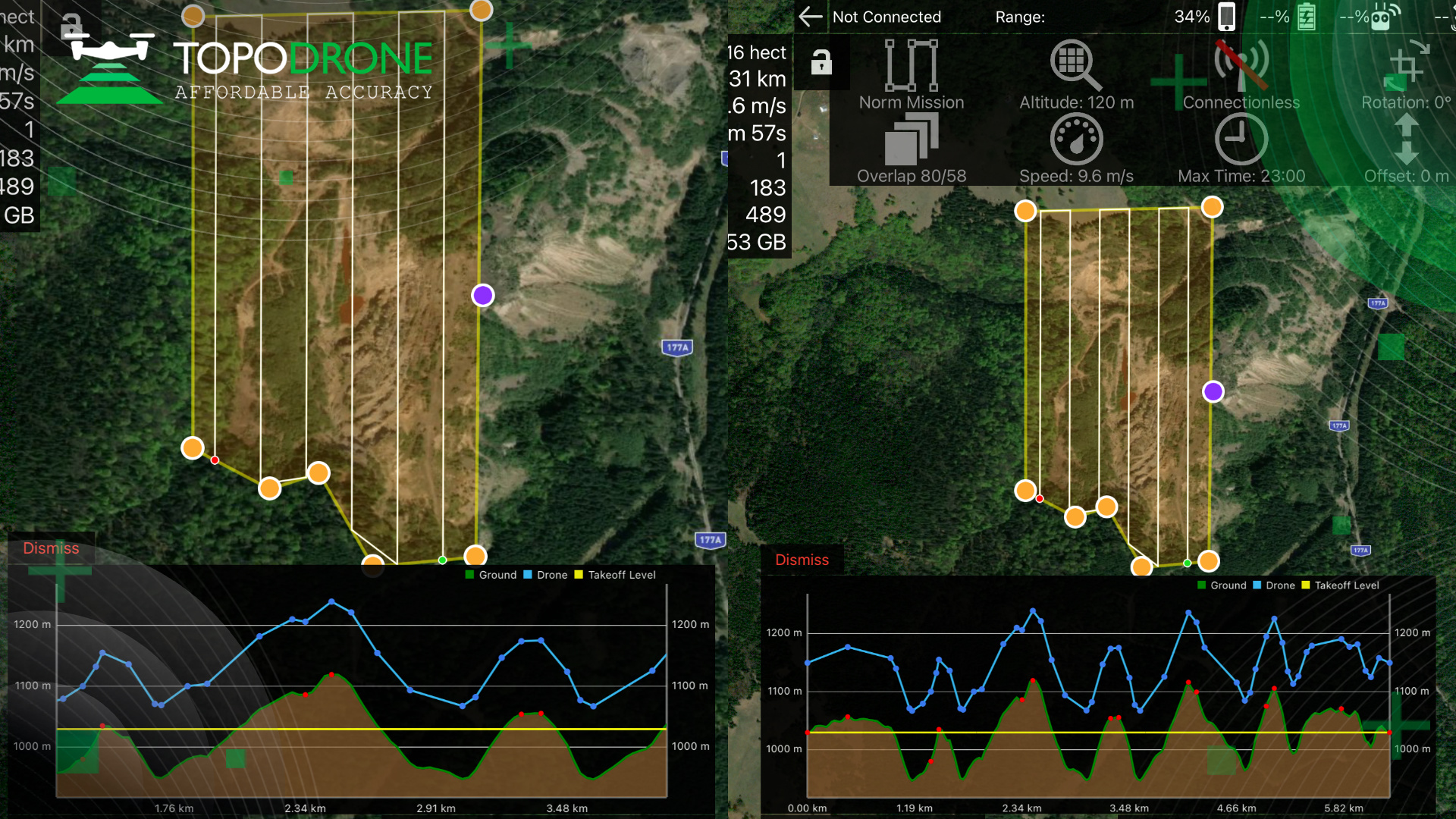

Fig. 4. Mission planning with terrain following mode.

The flight was conducted at an altitude of 120 meters above ground level (AGL) to ensure optimal coverage of the quarry. To maintain consistent overlap and ensure quality data acquisition, an 80% frontal overlap and 58% lateral overlap was maintained throughout the flight. The UAV was programmed to maintain a speed of 9.6 meters per second while incorporating terrain awareness, which helped the aircraft maintain a consistent distance from the ground, ensuring consistent overlap during data acquisition.

Data processing:

It is critical that all steps of data processing were done in the field to evaluate the quality of the data, since the area is far from the BDS Topografie SRL office and it would not be necessary to spend time to return to the site if something went wrong.

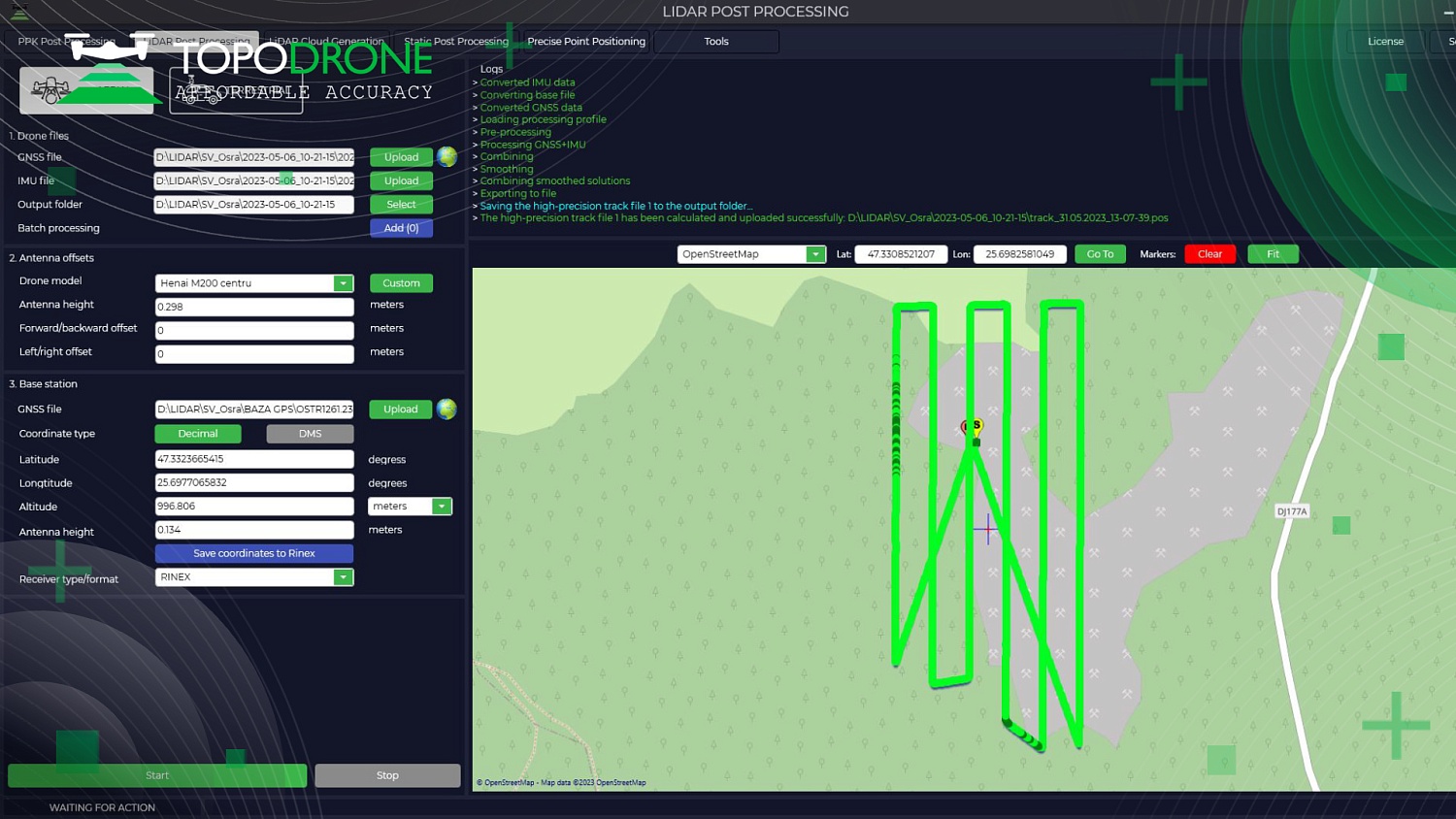

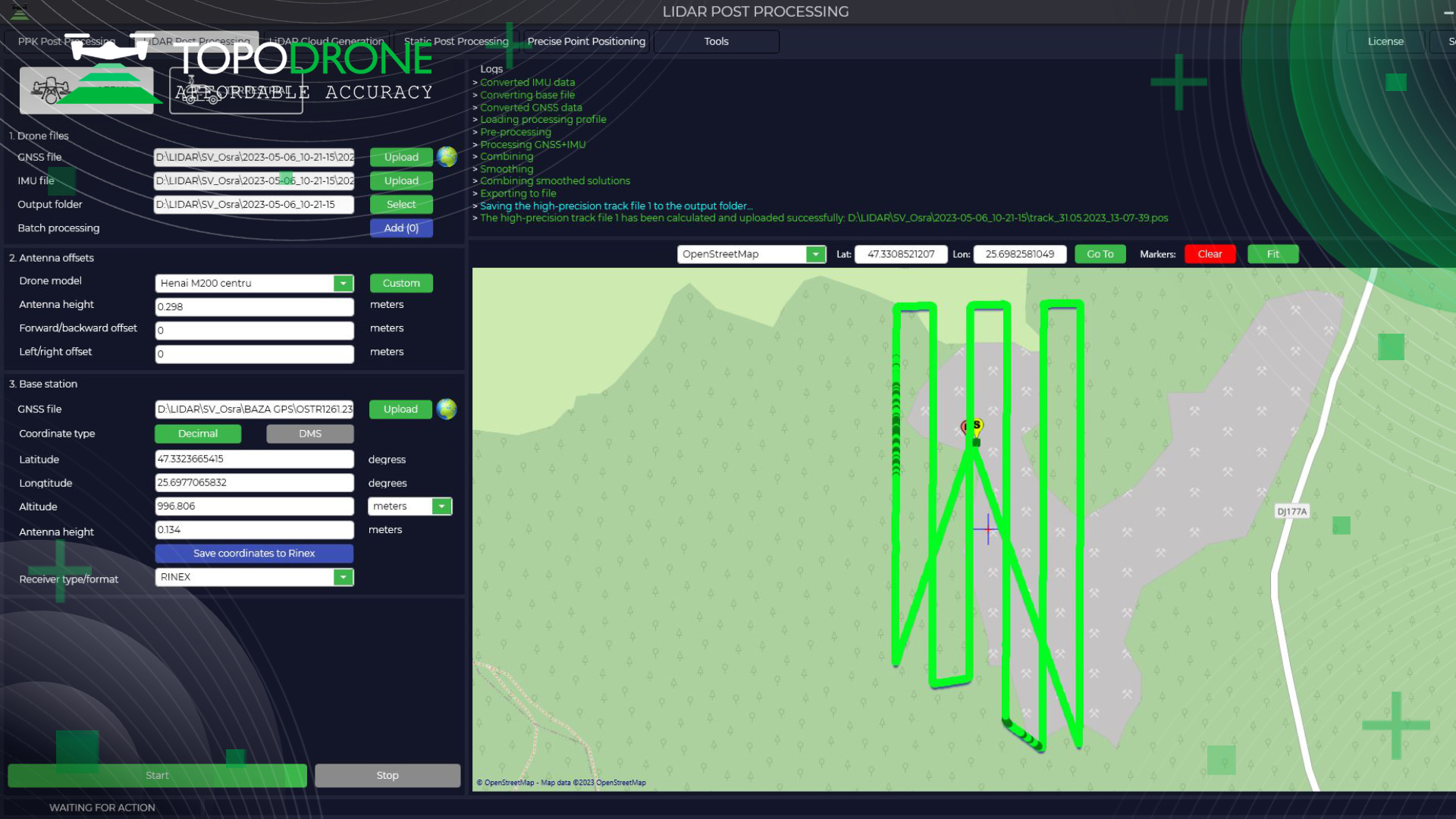

First, Semion post-processed the flight trajectories using TOPODRONE Post Processing software and then generated an accurate point cloud in the Romanian coordinate system.

After that, an automatic classification of the point cloud was performed to obtain a real terrain level. We would like to draw your attention to the high density of the point cloud and the triple return, which allowed to obtain accurate and detailed terrain structure even in dense forest area.

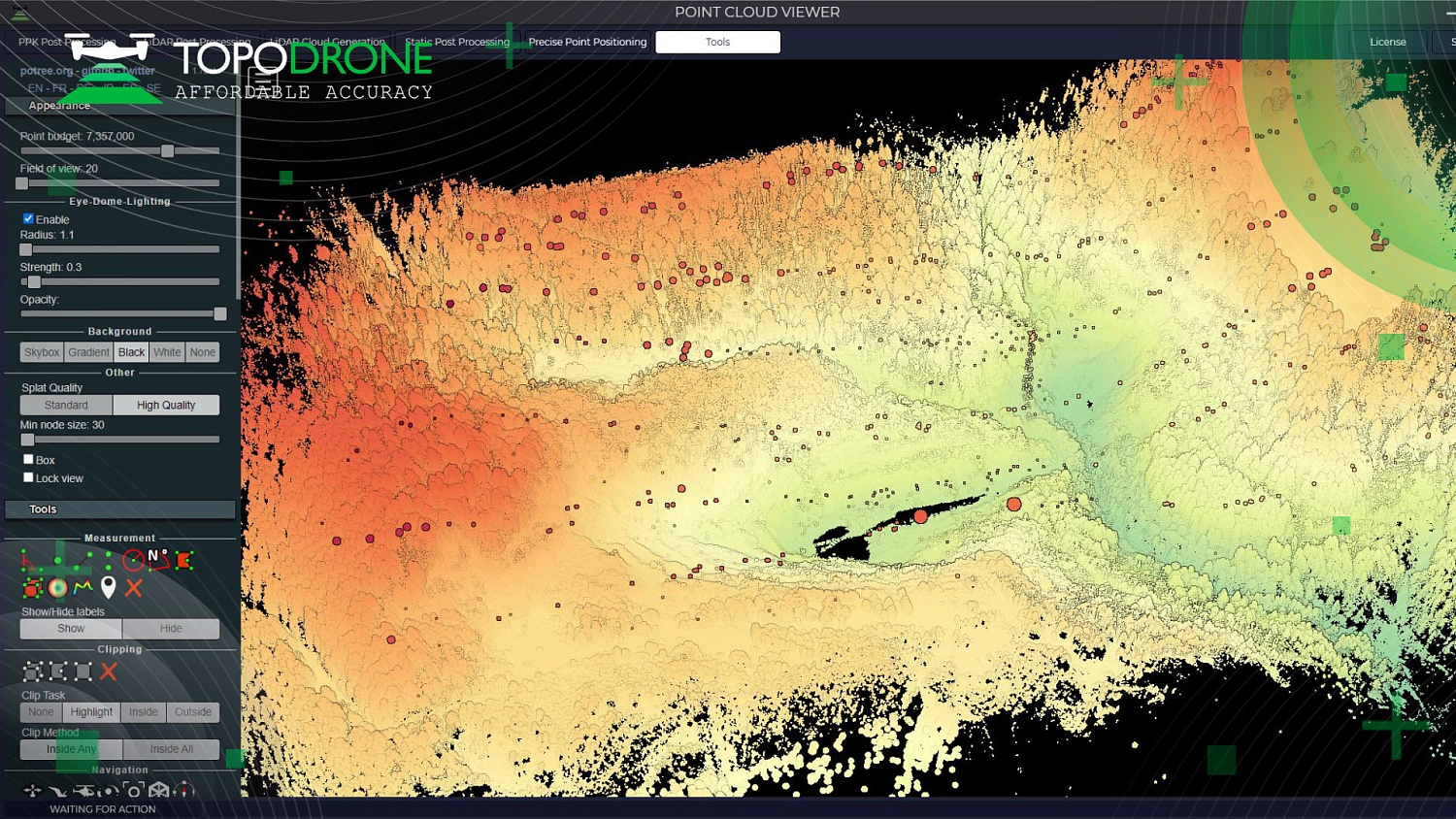

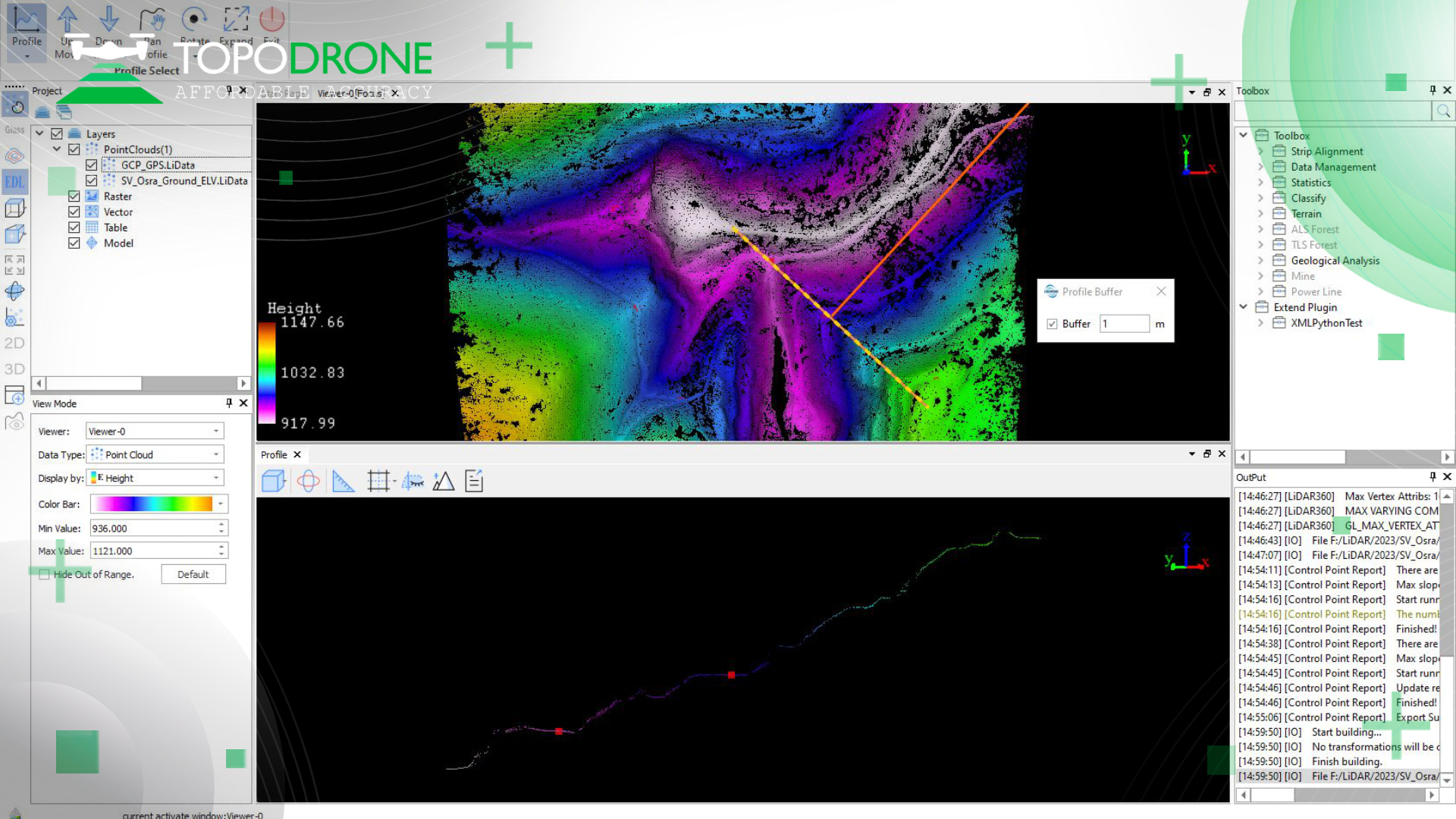

Fig. 5. LiDAR data processing in the TOPODRONE Post Processing software.

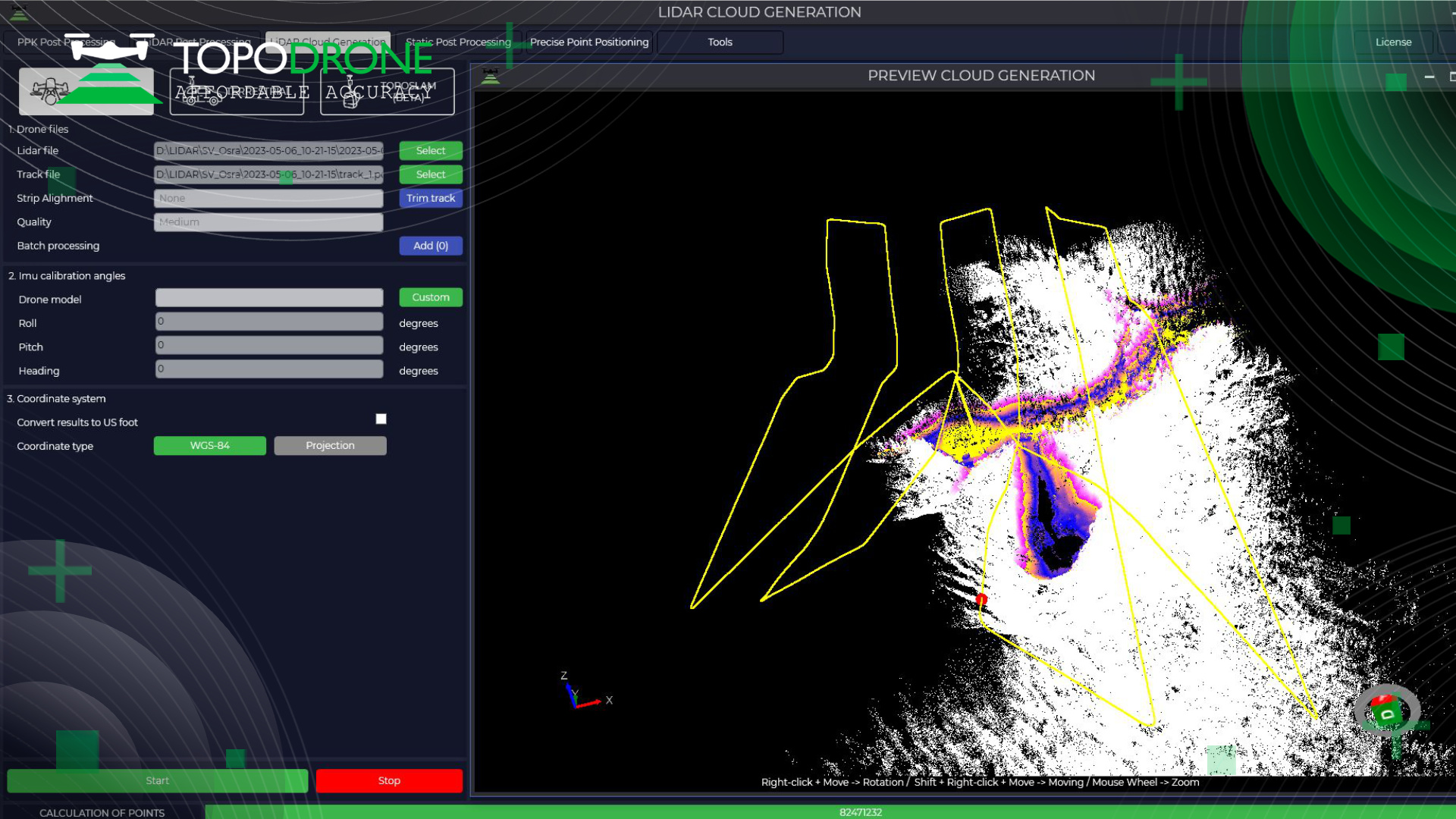

Fig. 6. LiDAR data processing in the TOPODRONE Post Processing software.

Fig. 7. LiDAR data processing in the TOPODRONE Post Processing software.

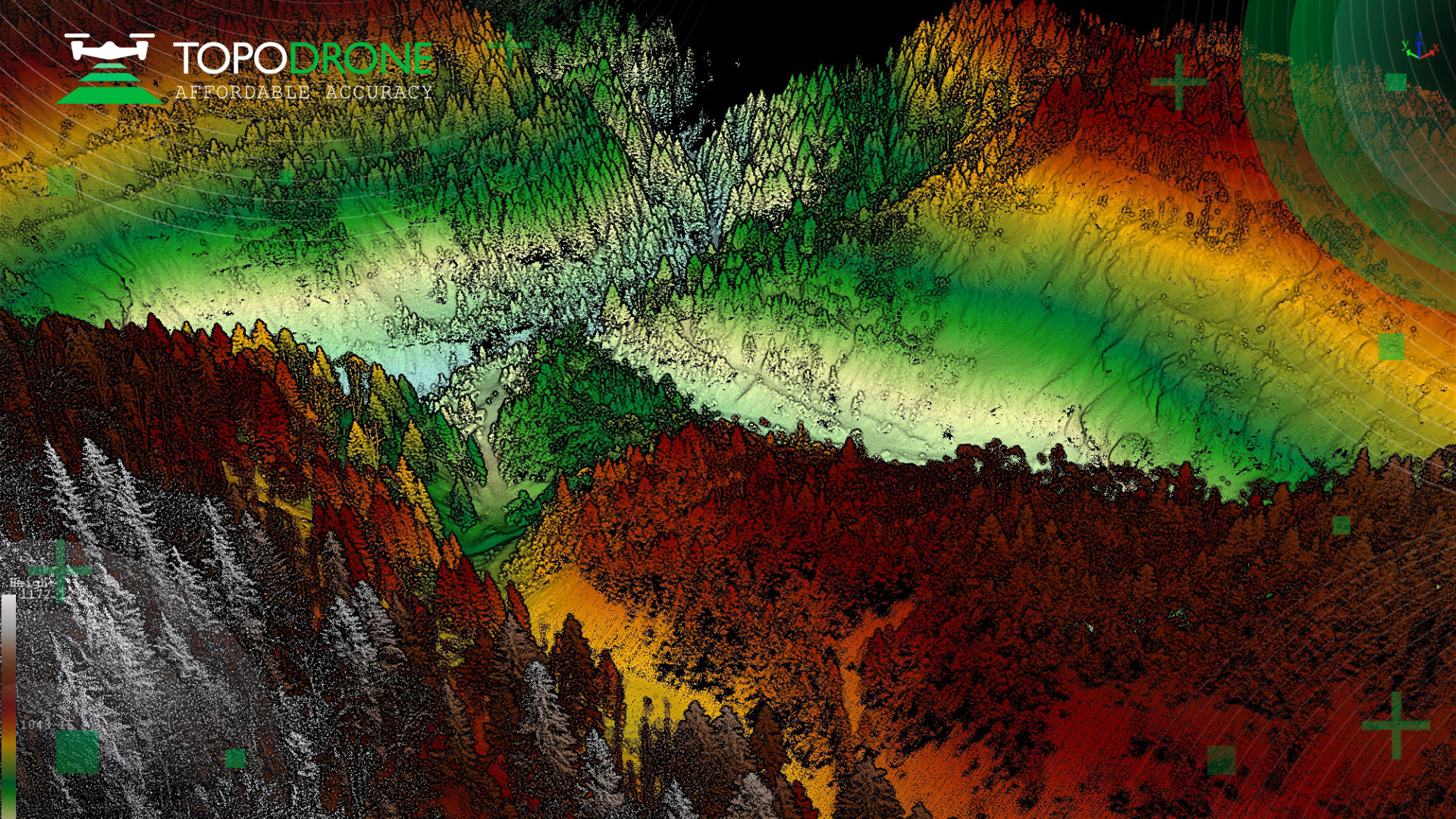

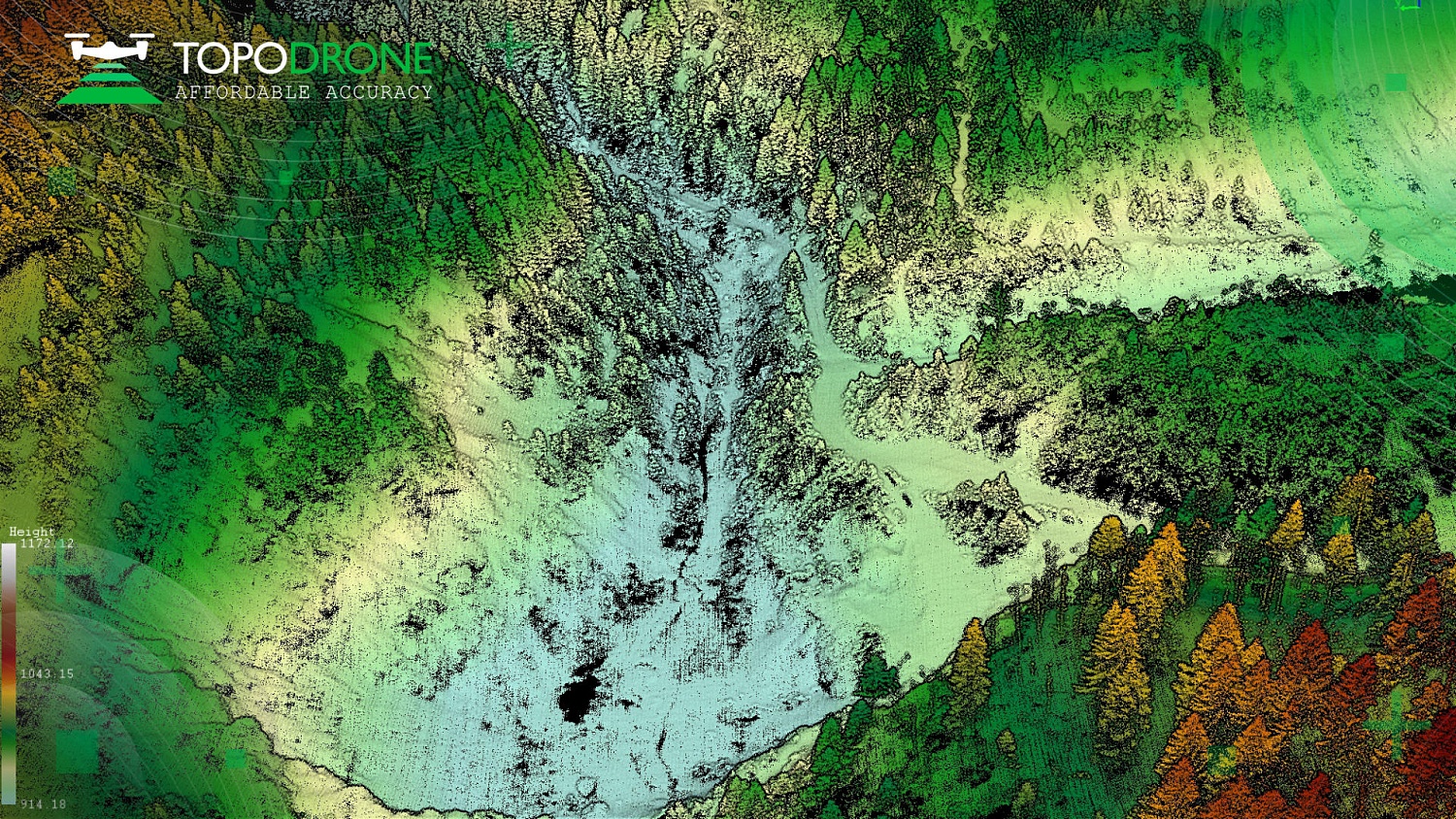

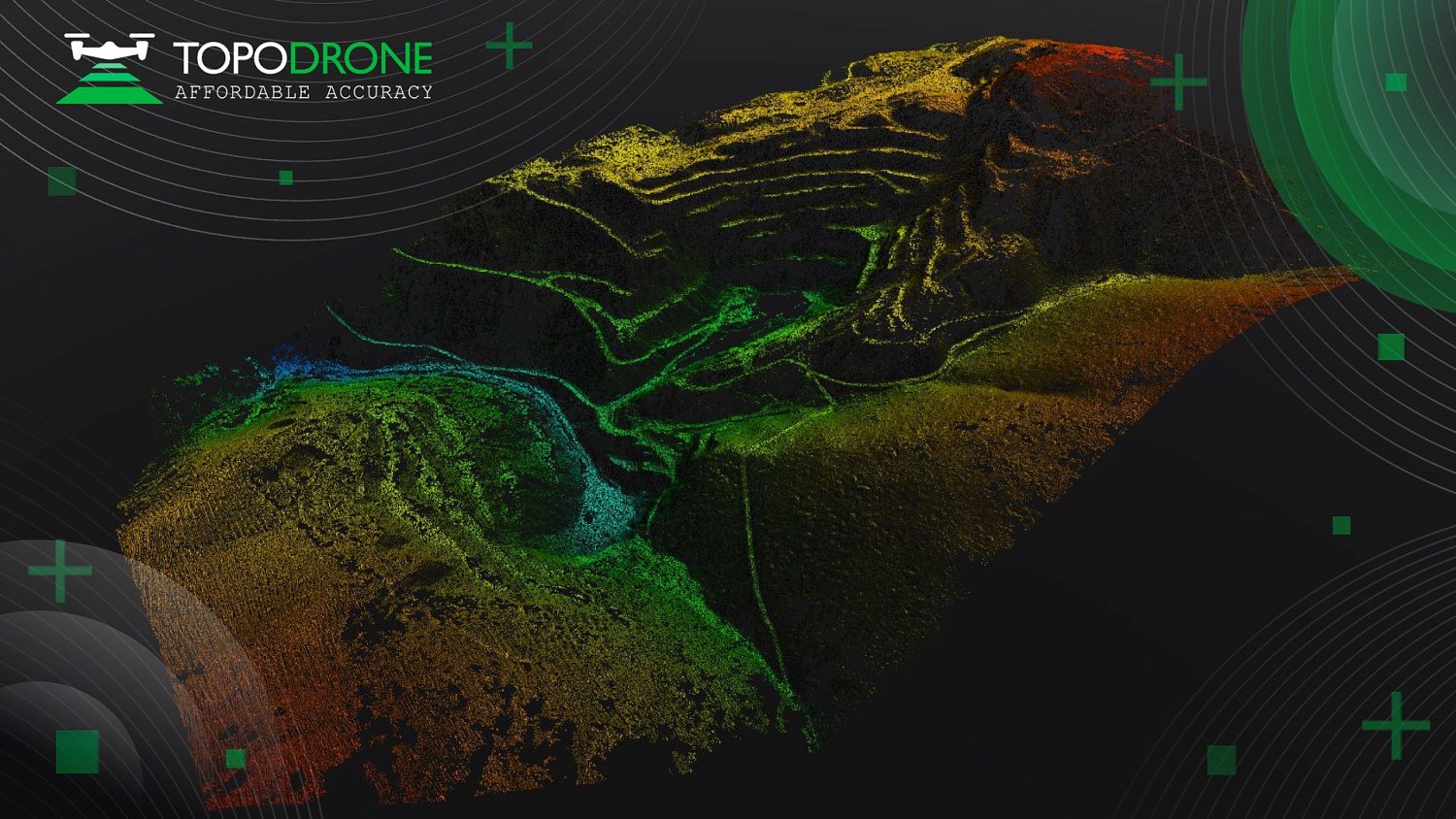

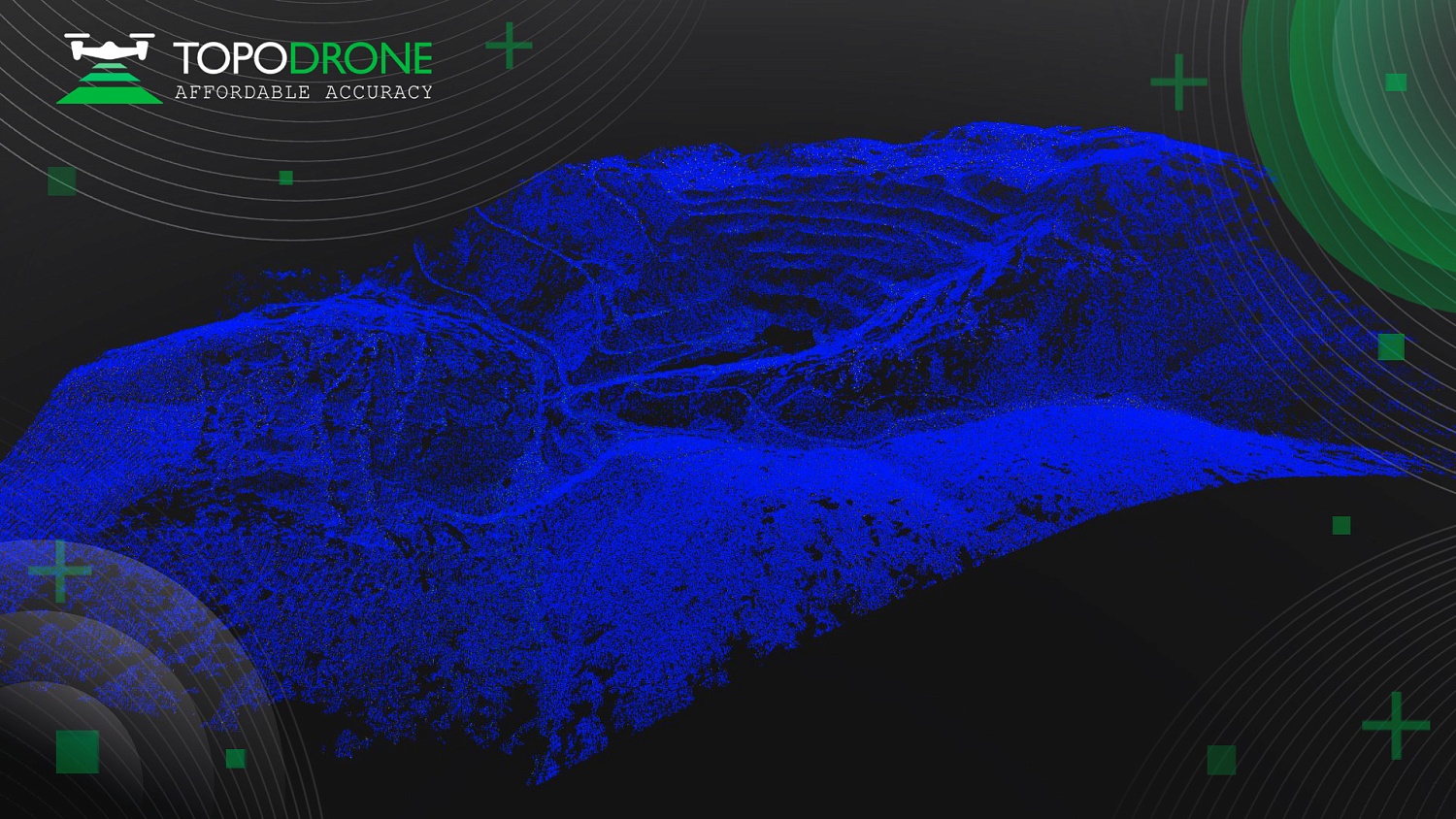

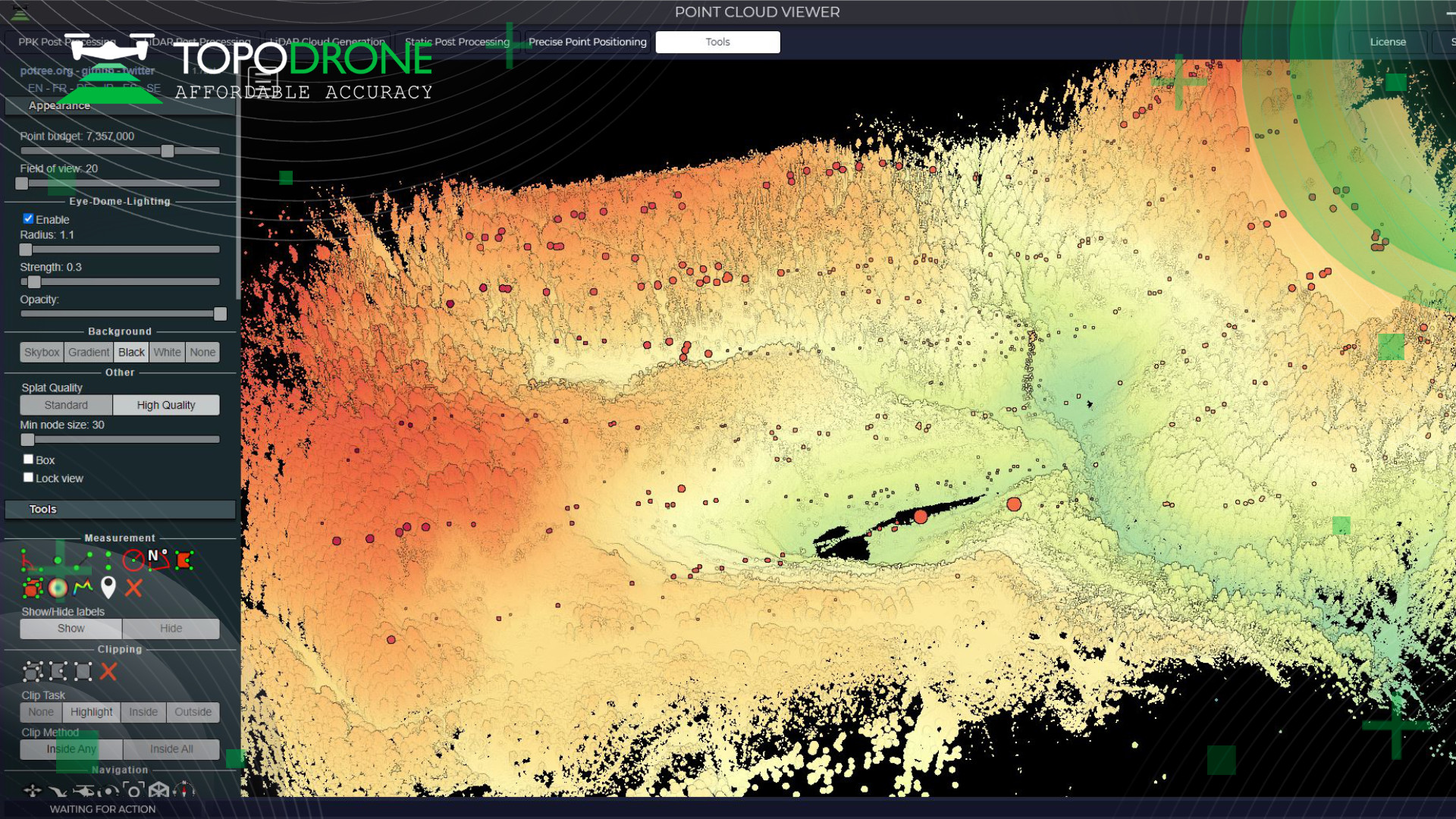

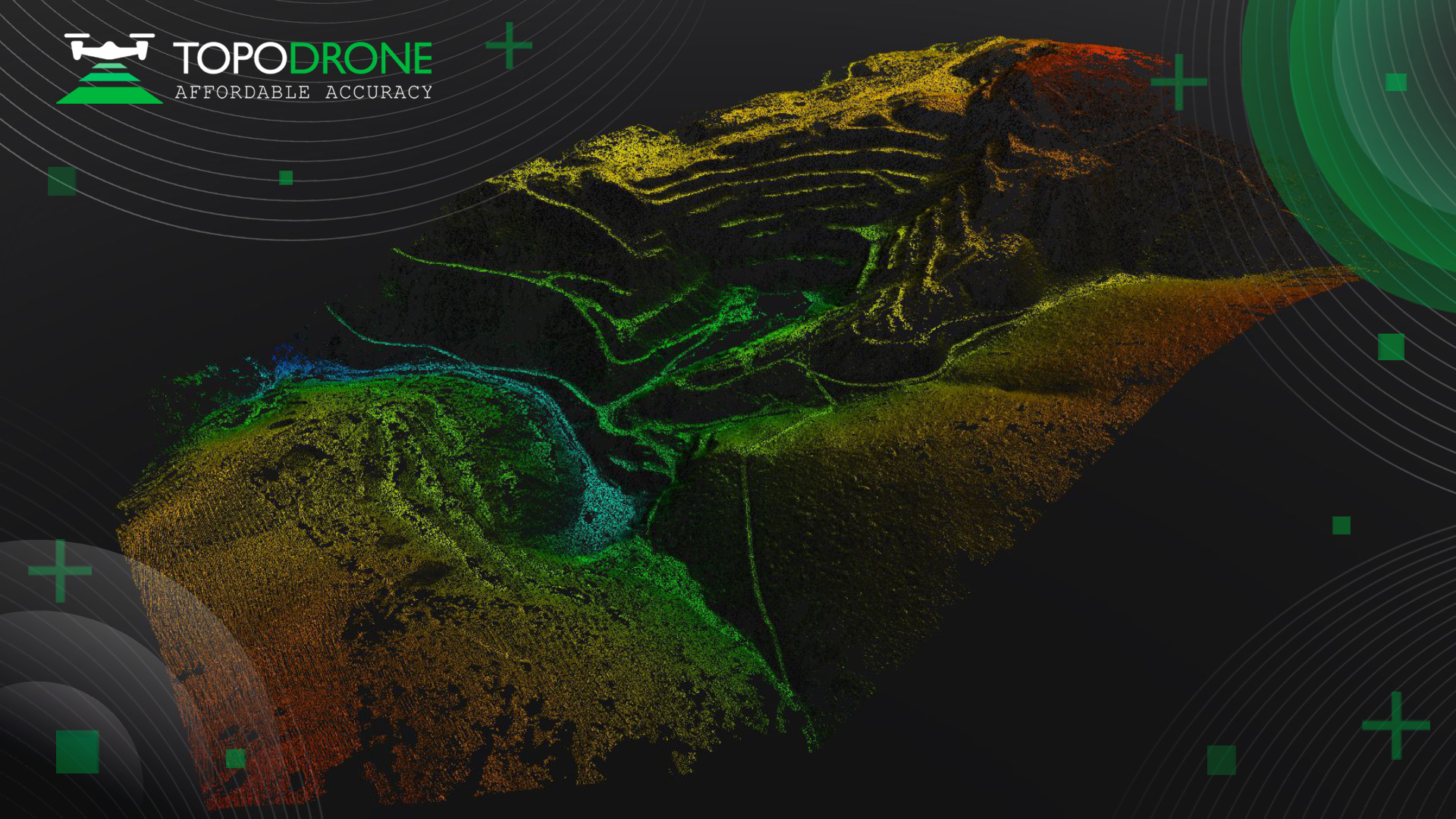

Fig. 8. LiDAR point cloud over the mining site area.

Fig. 9. LiDAR point cloud over the mining site area.

Fig. 10. LiDAR point cloud over the mining site area.

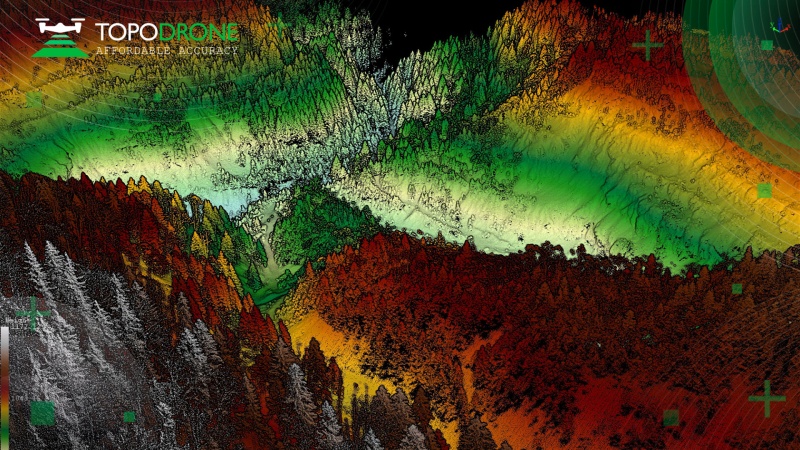

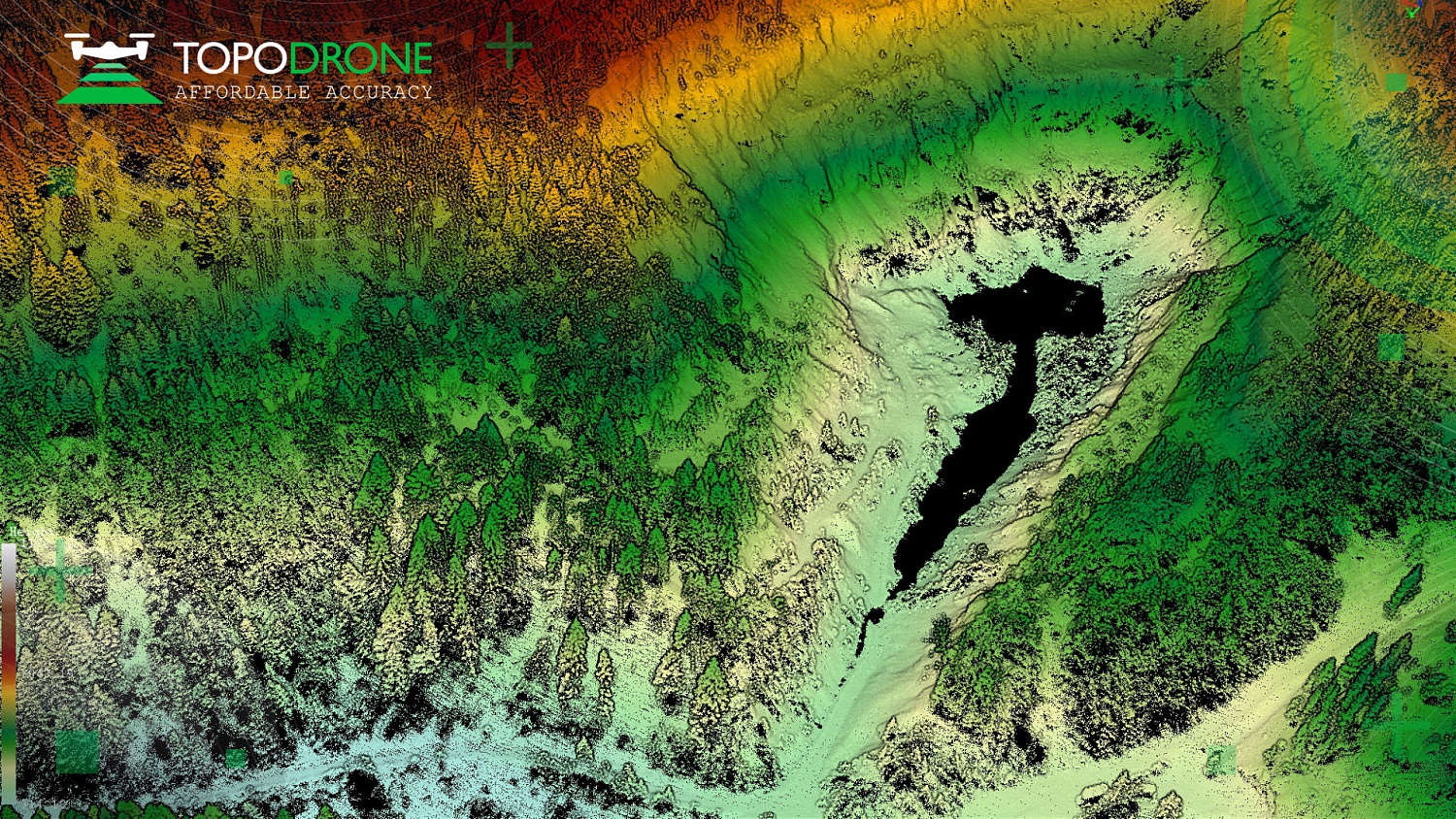

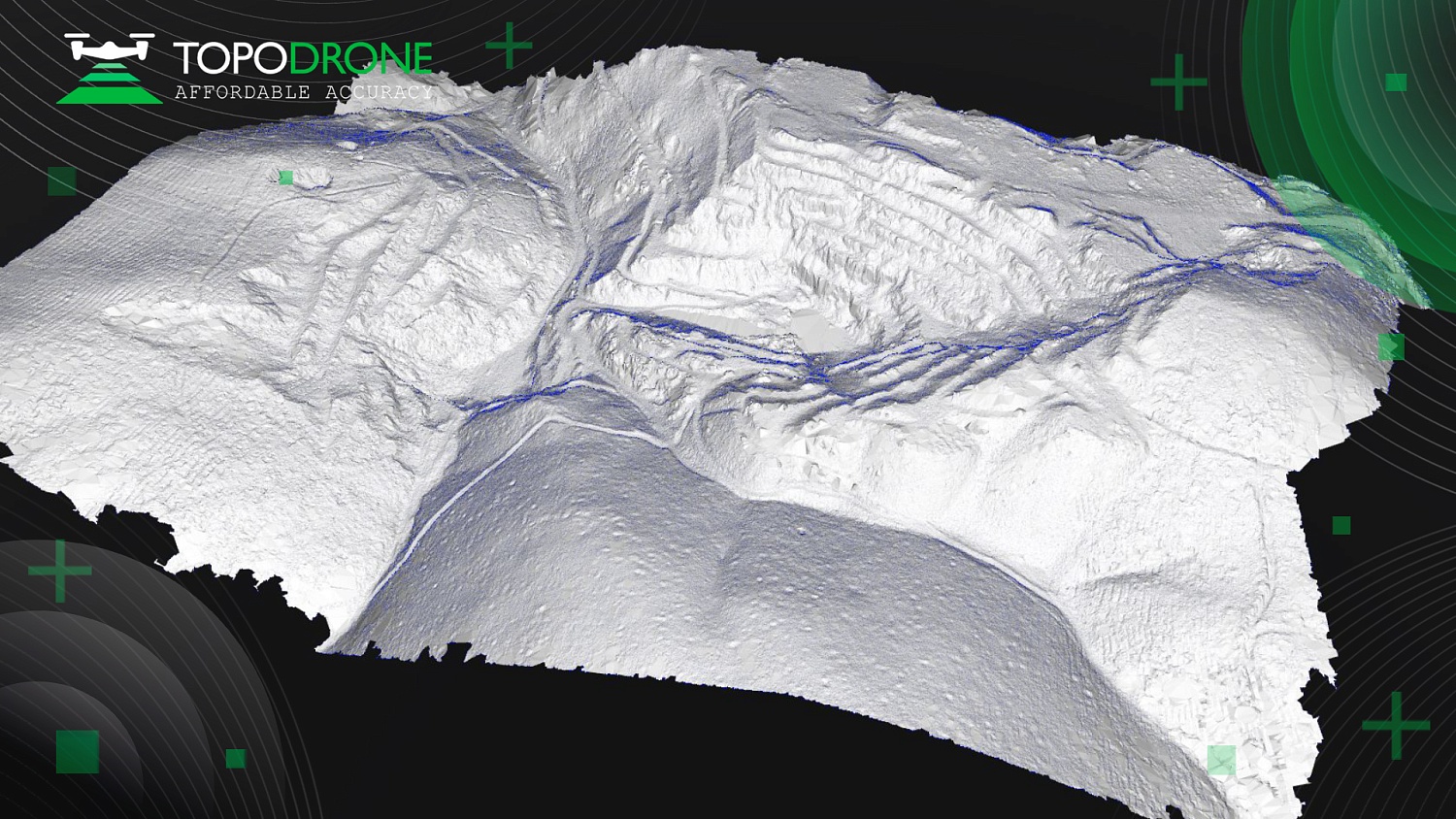

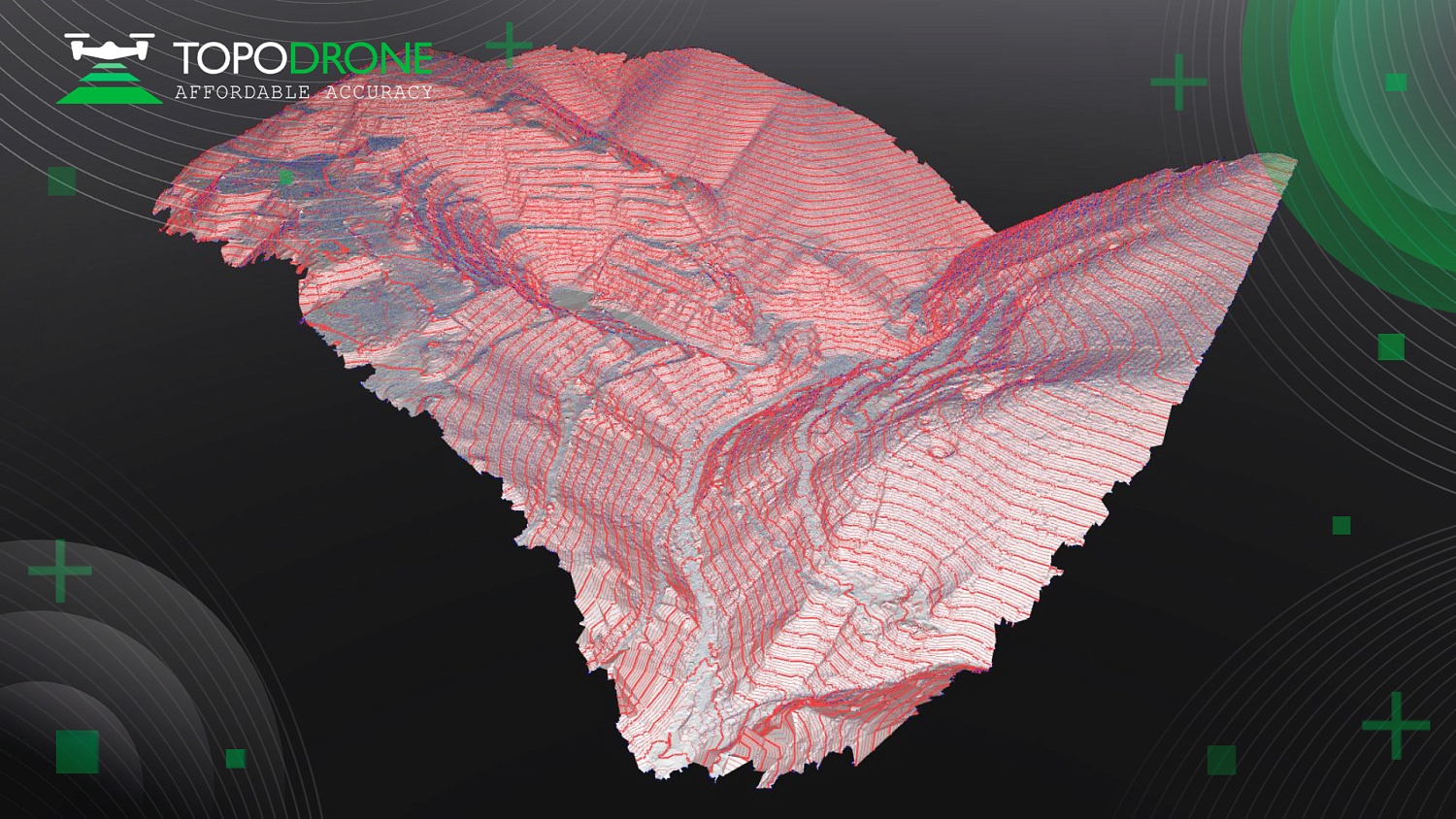

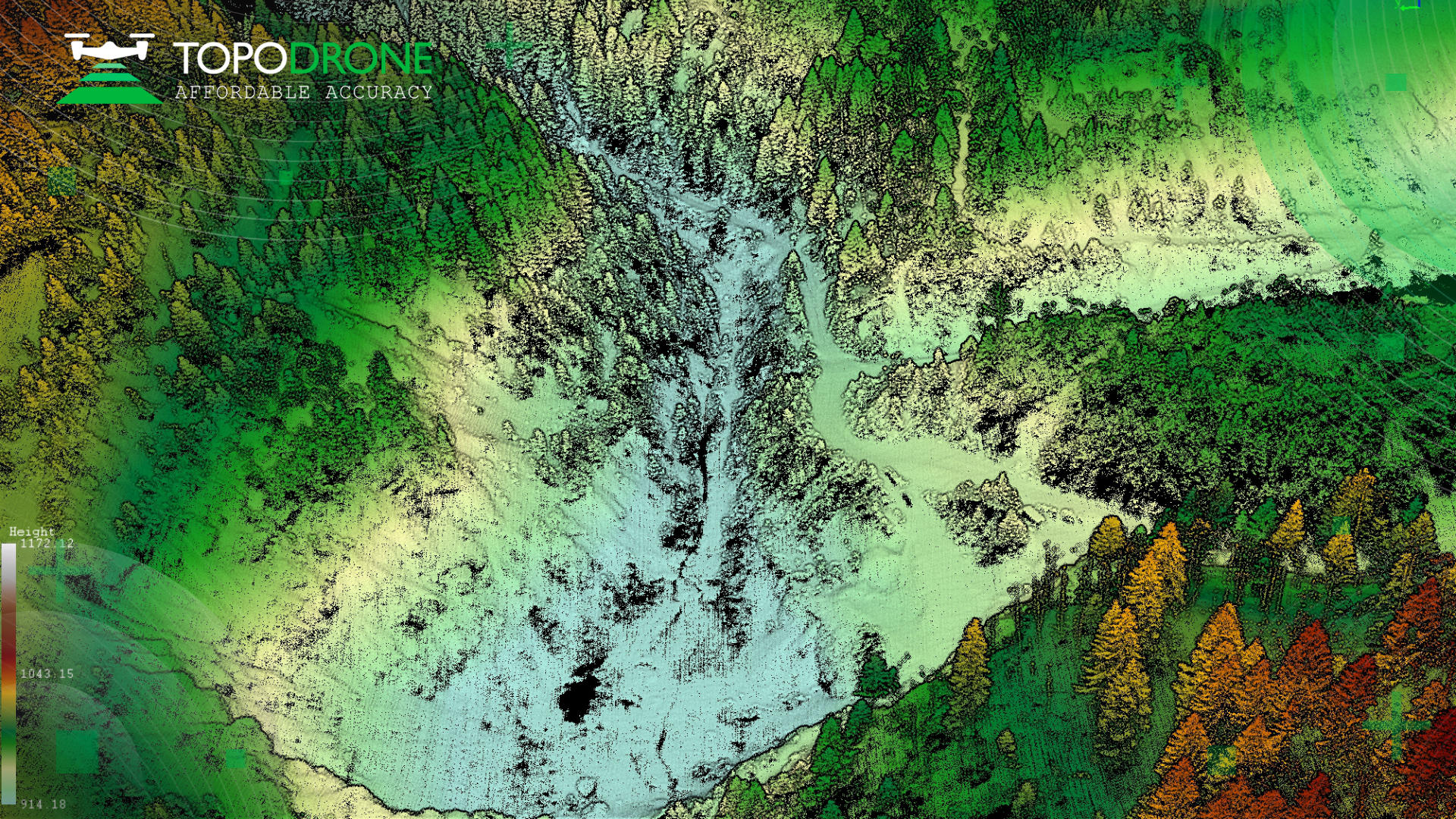

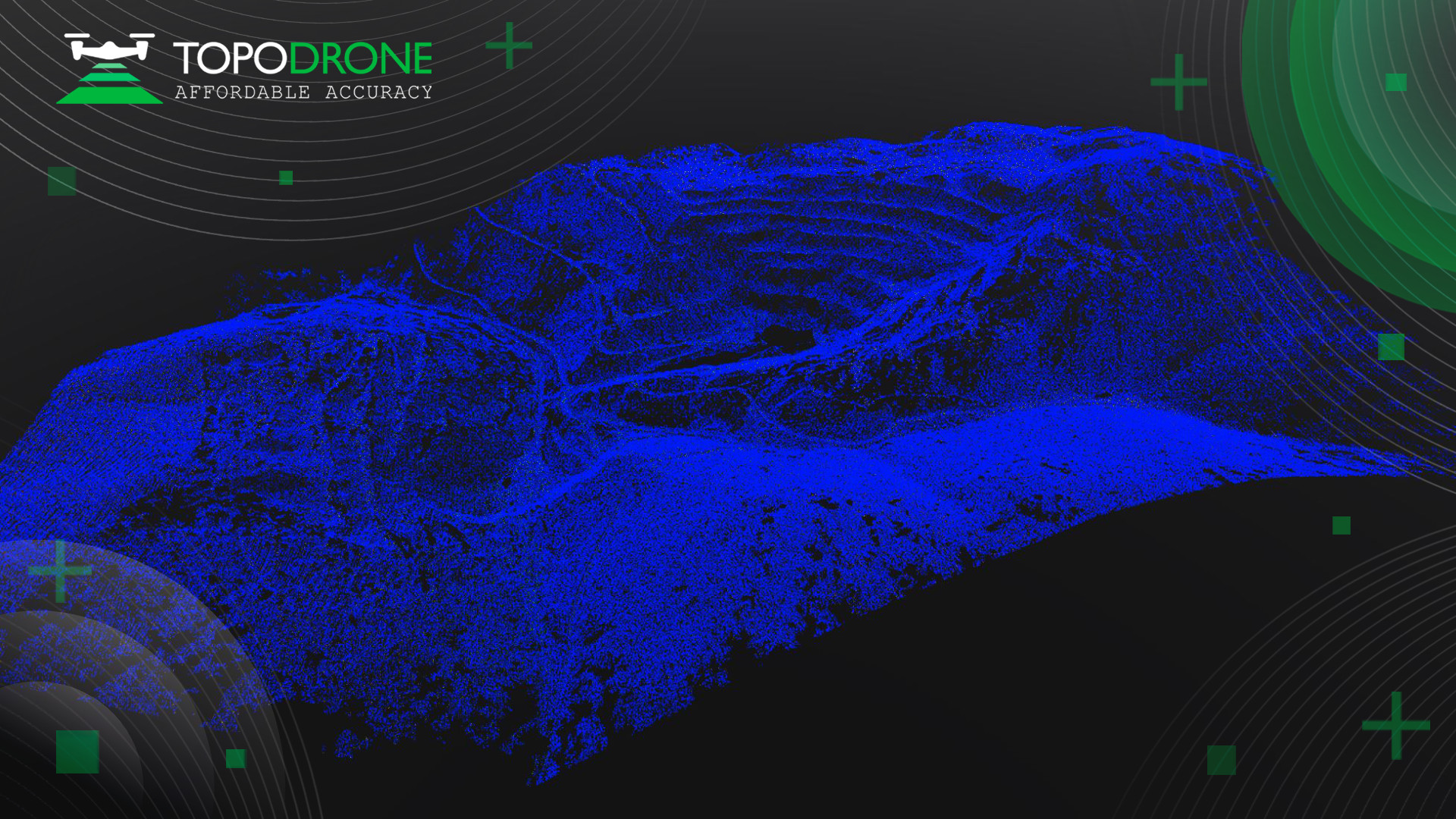

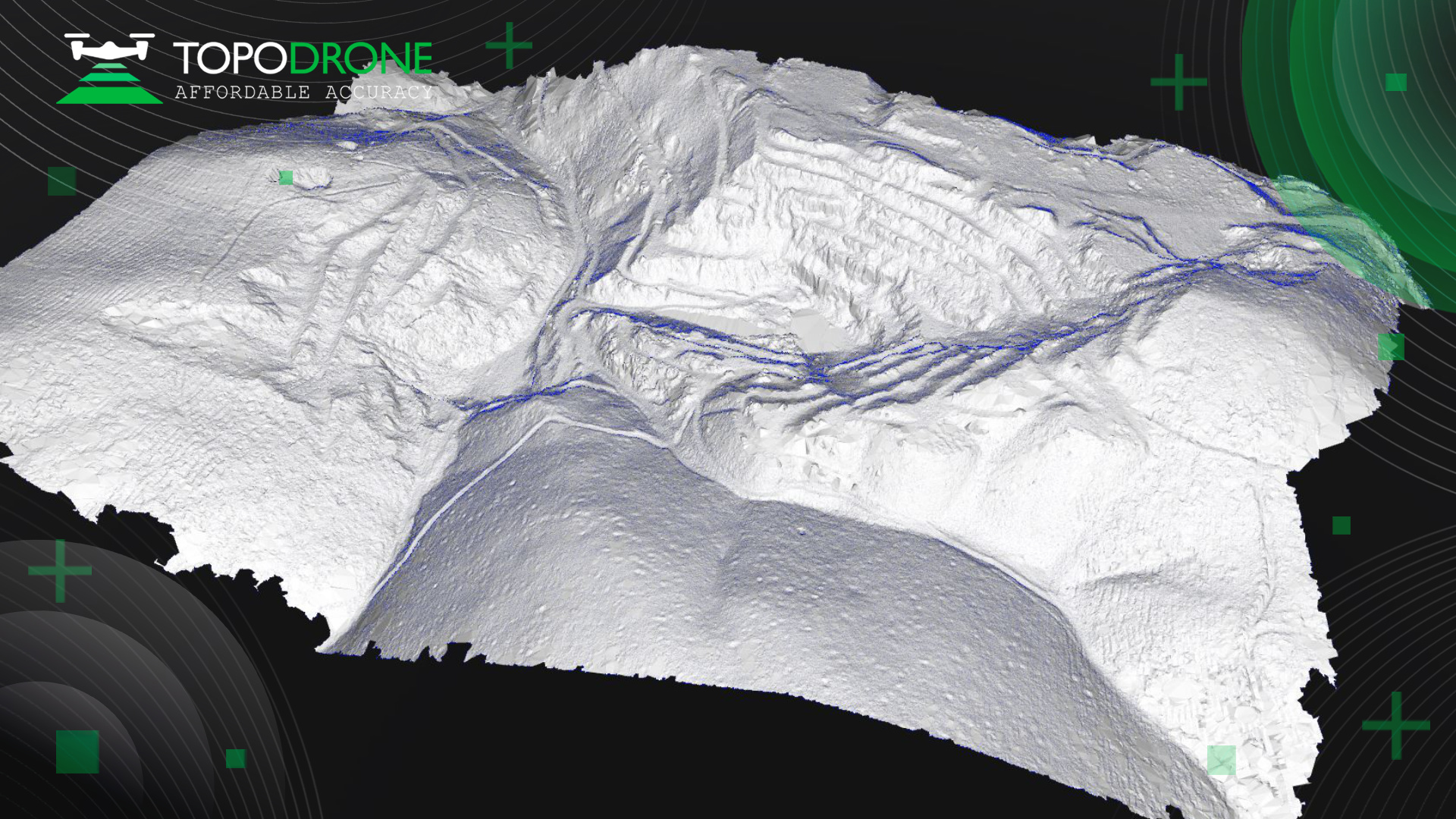

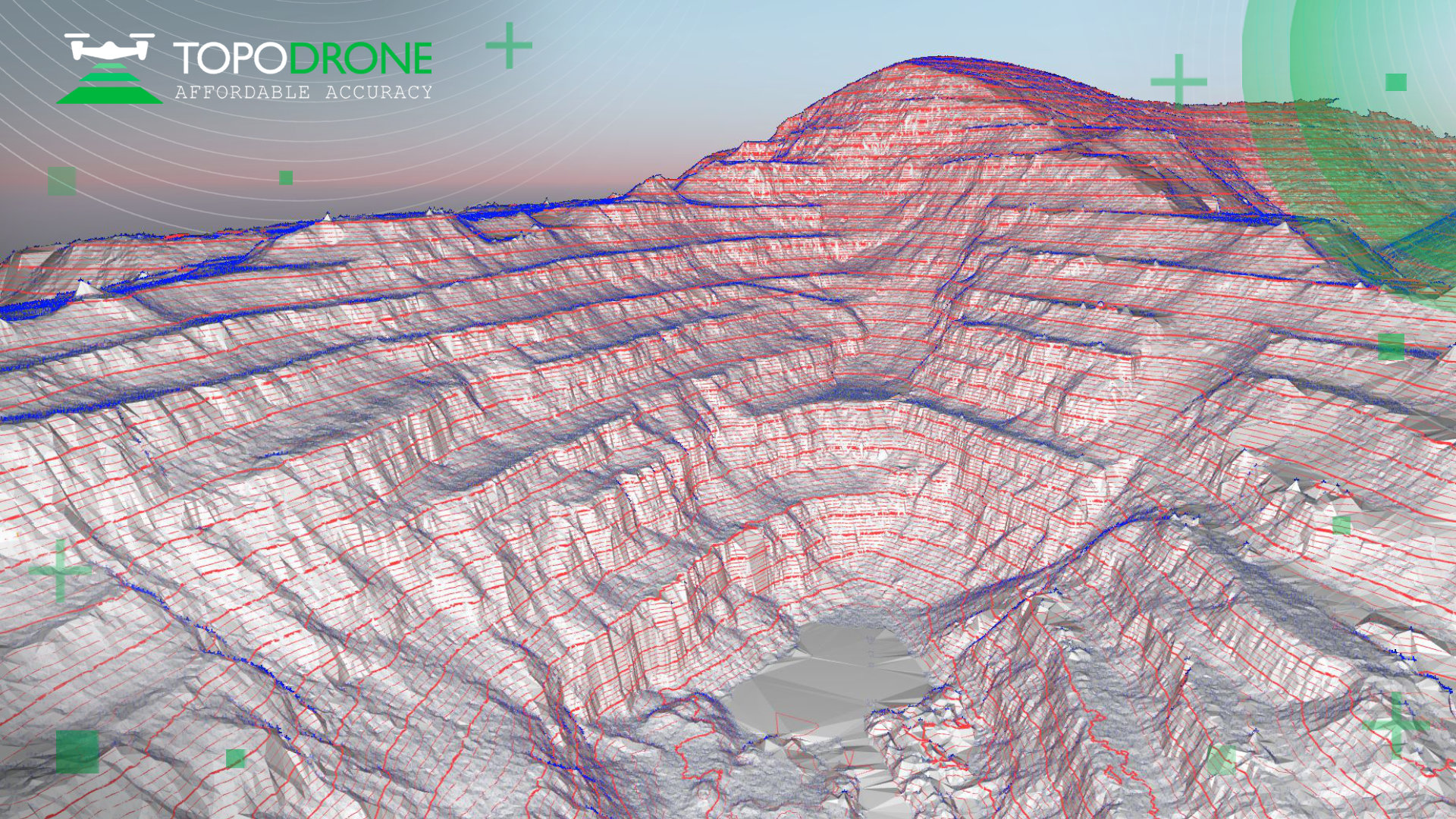

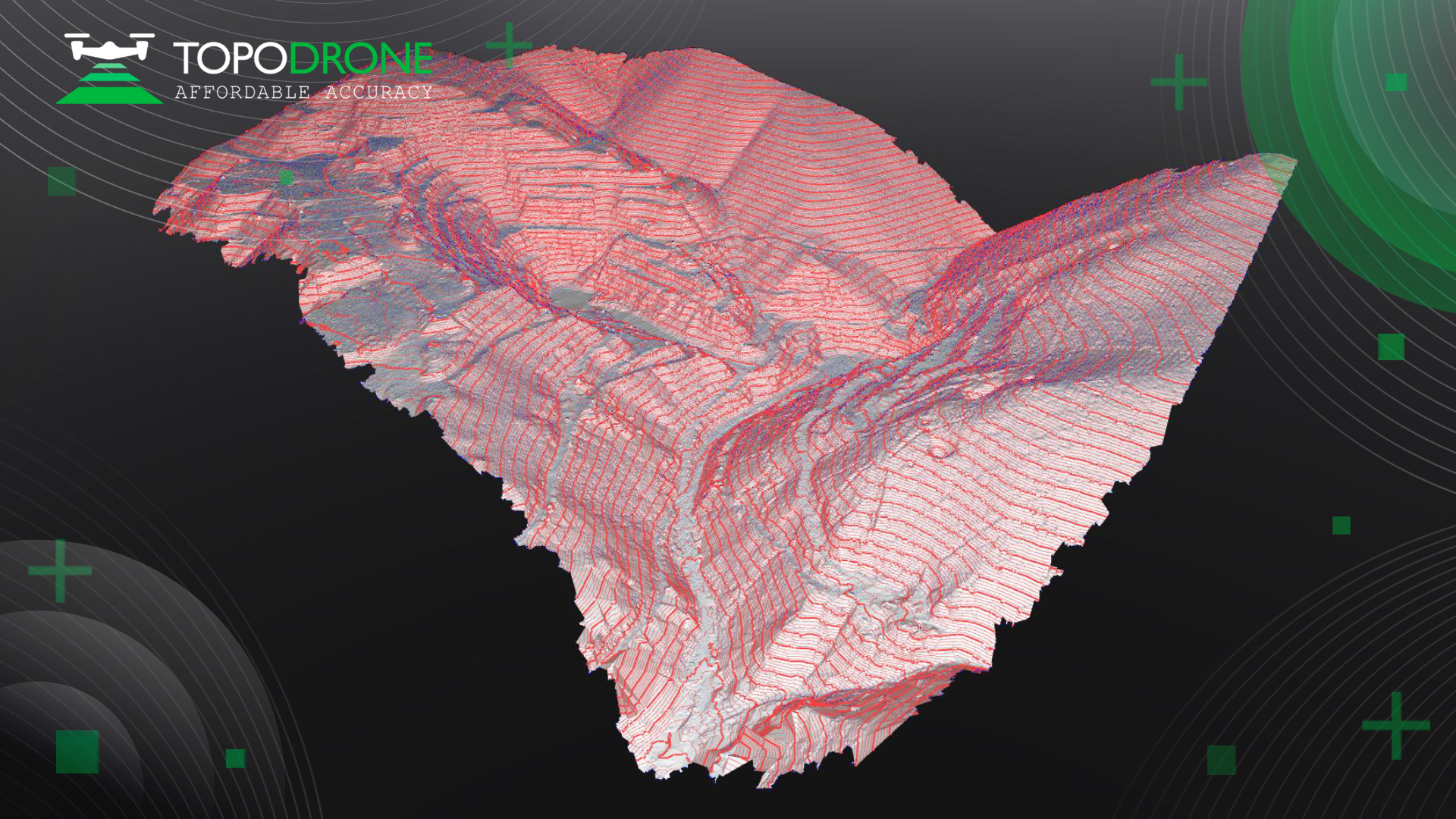

Fig. 11. Terrain model reconstructed from classified LiDAR data.

Fig. 12. Terrain model reconstructed from classified LiDAR data.

Fig. 13. Terrain model reconstructed from classified LiDAR data.

Fig. 14. Terrain model reconstructed from classified LiDAR data.

Fig. 15. Terrain model reconstructed from classified LiDAR data.

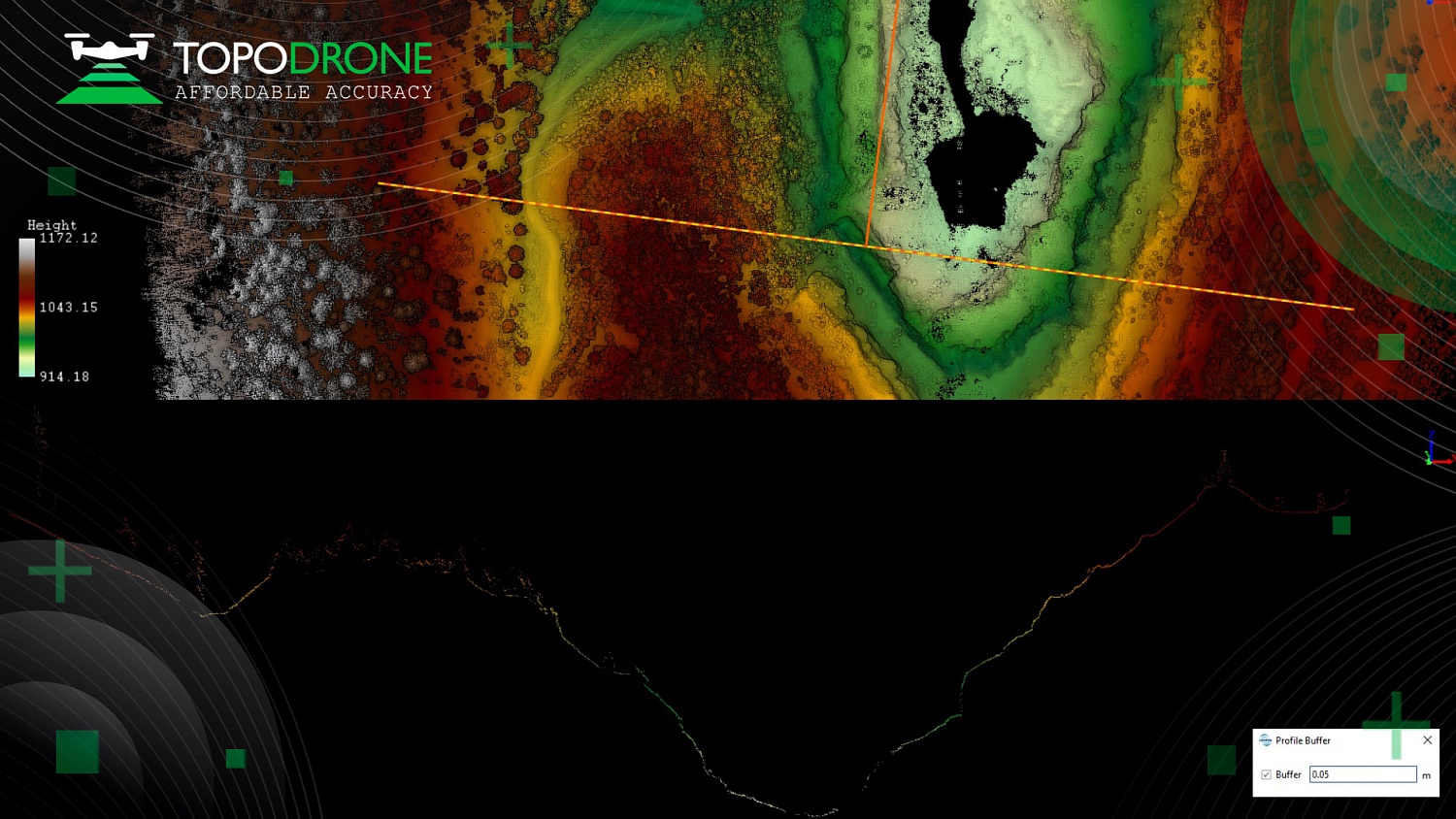

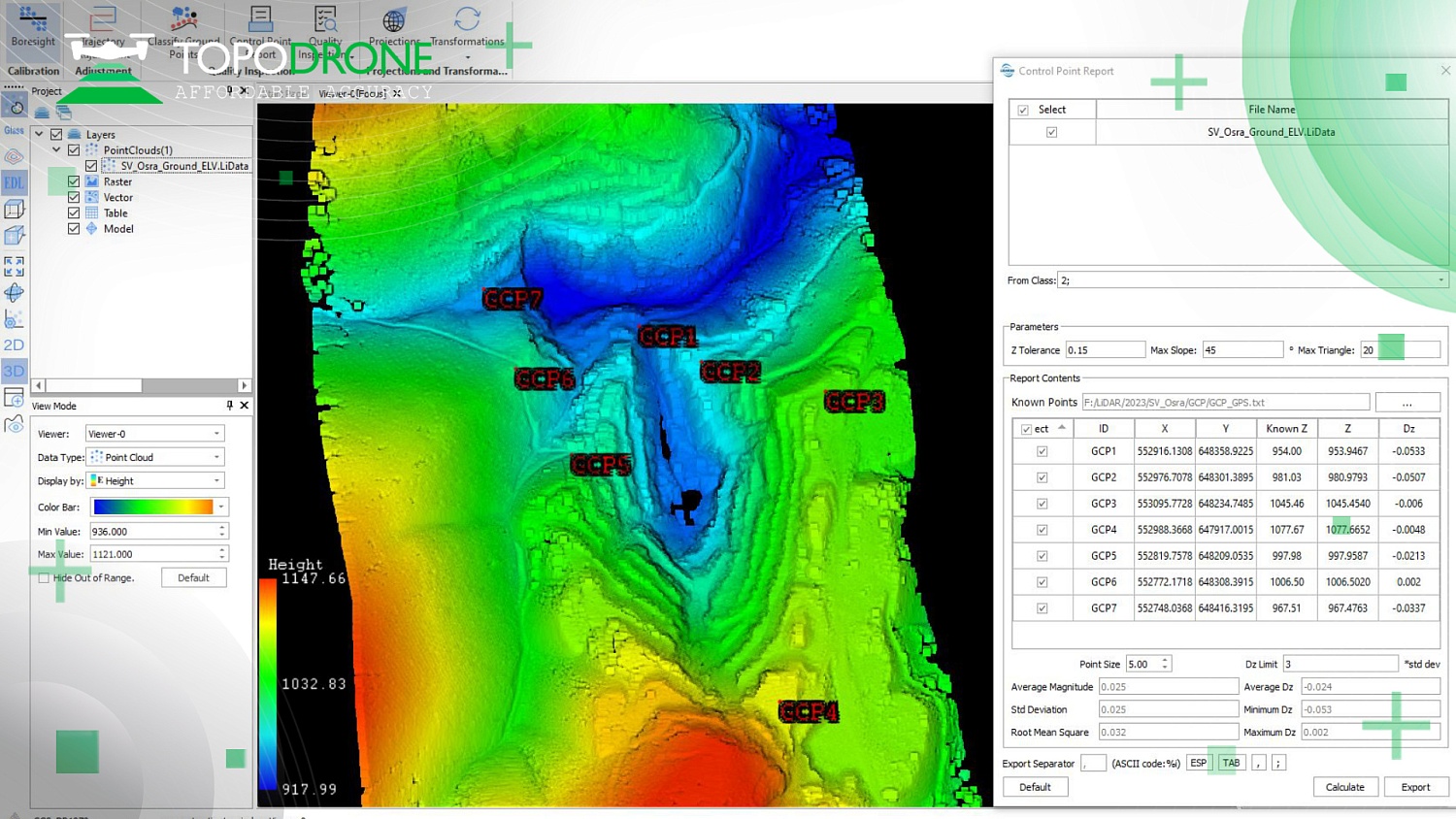

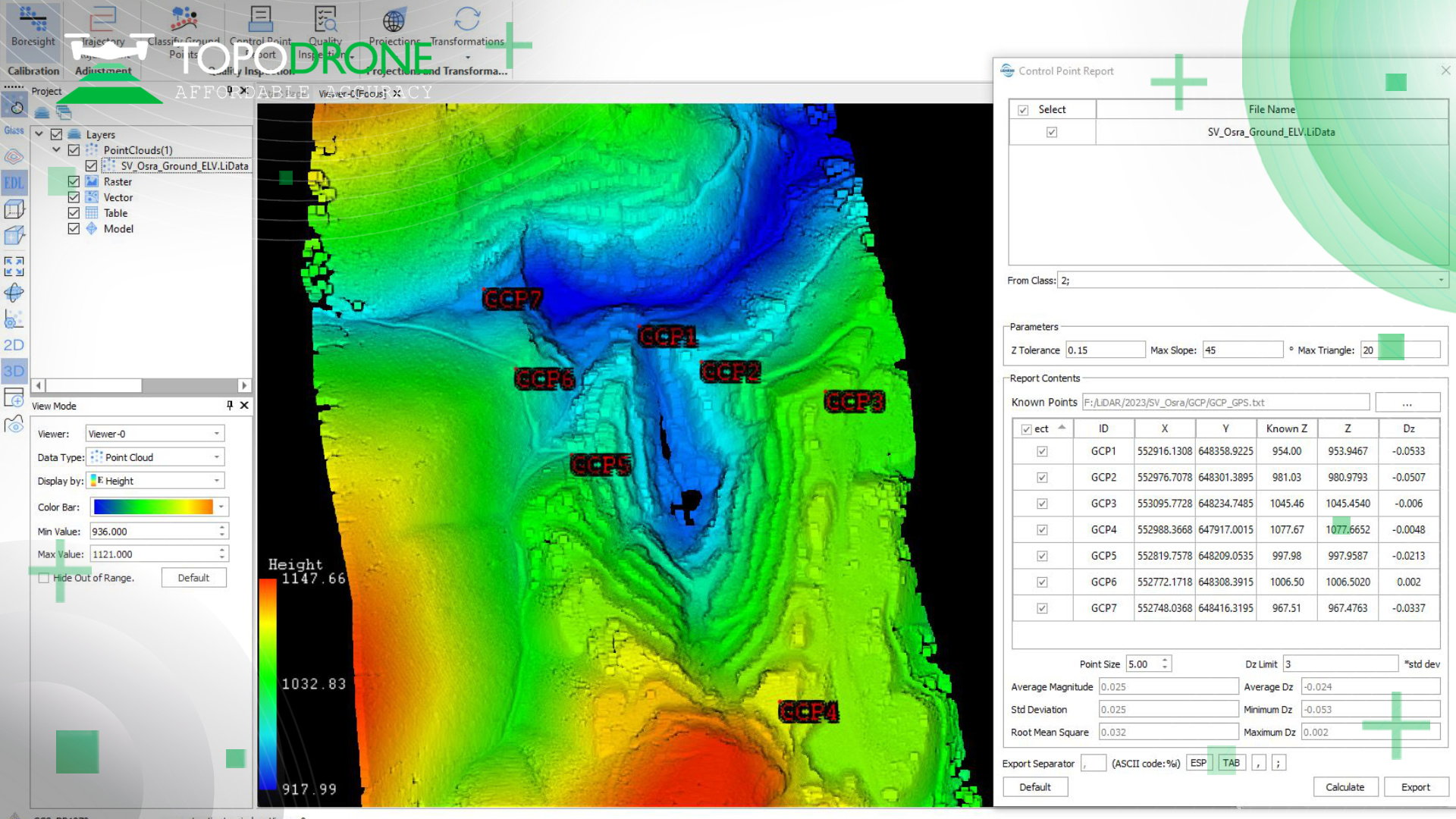

Verification of LiDAR data:

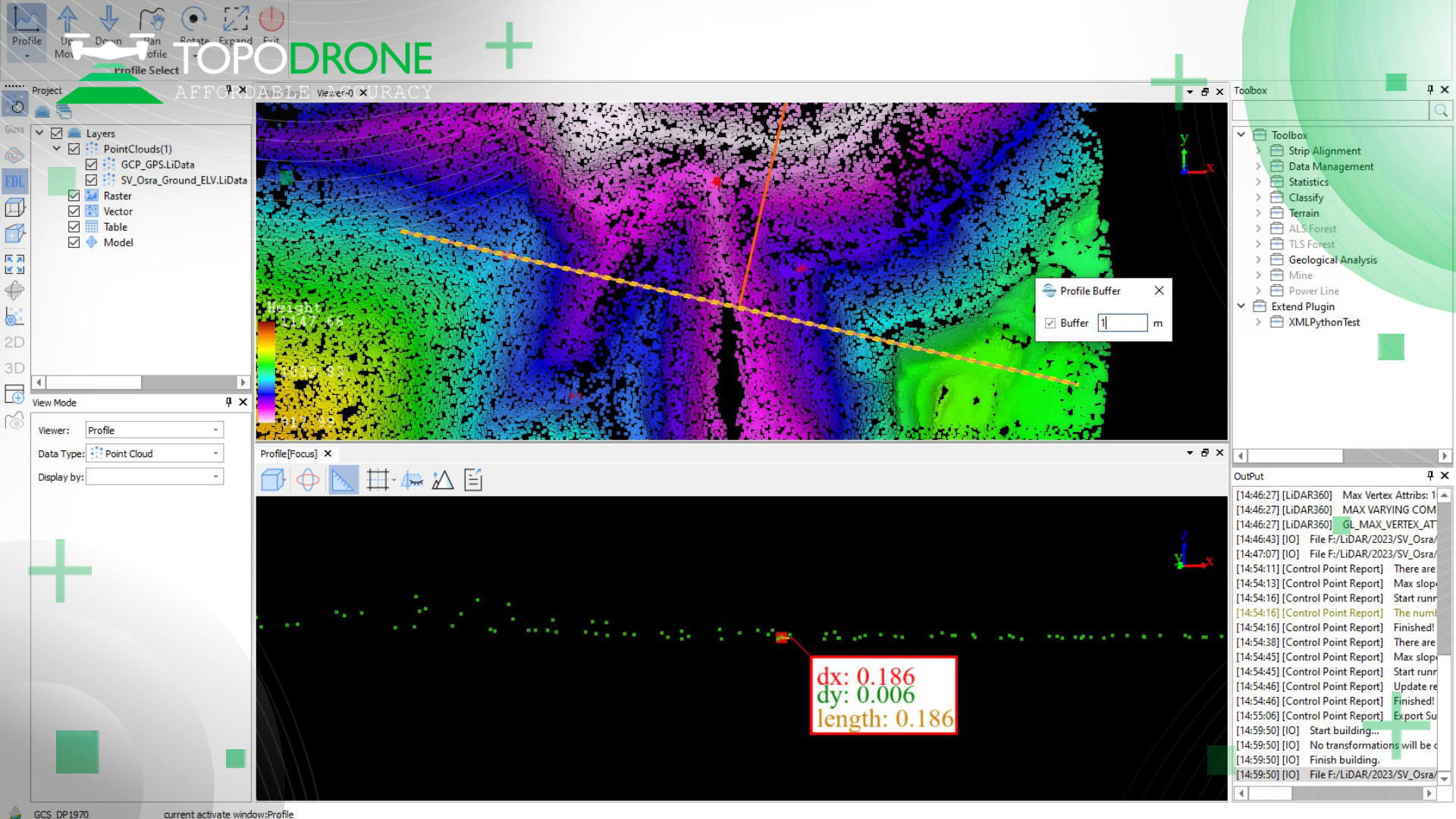

To ensure the accuracy and reliability of the collected LiDAR data, seven ground control points (GCP) were measured using GNSS technology. These GCPs were used as control points for the elevation measurements. The difference in elevation between the GCP points ranged from 0.002 meters to -0.053 meters, demonstrating the high accuracy of the LiDAR data collected by the TOPODRONE LiDAR 200+ system.

Fig. 16. Control points location and automatic accuracy report.

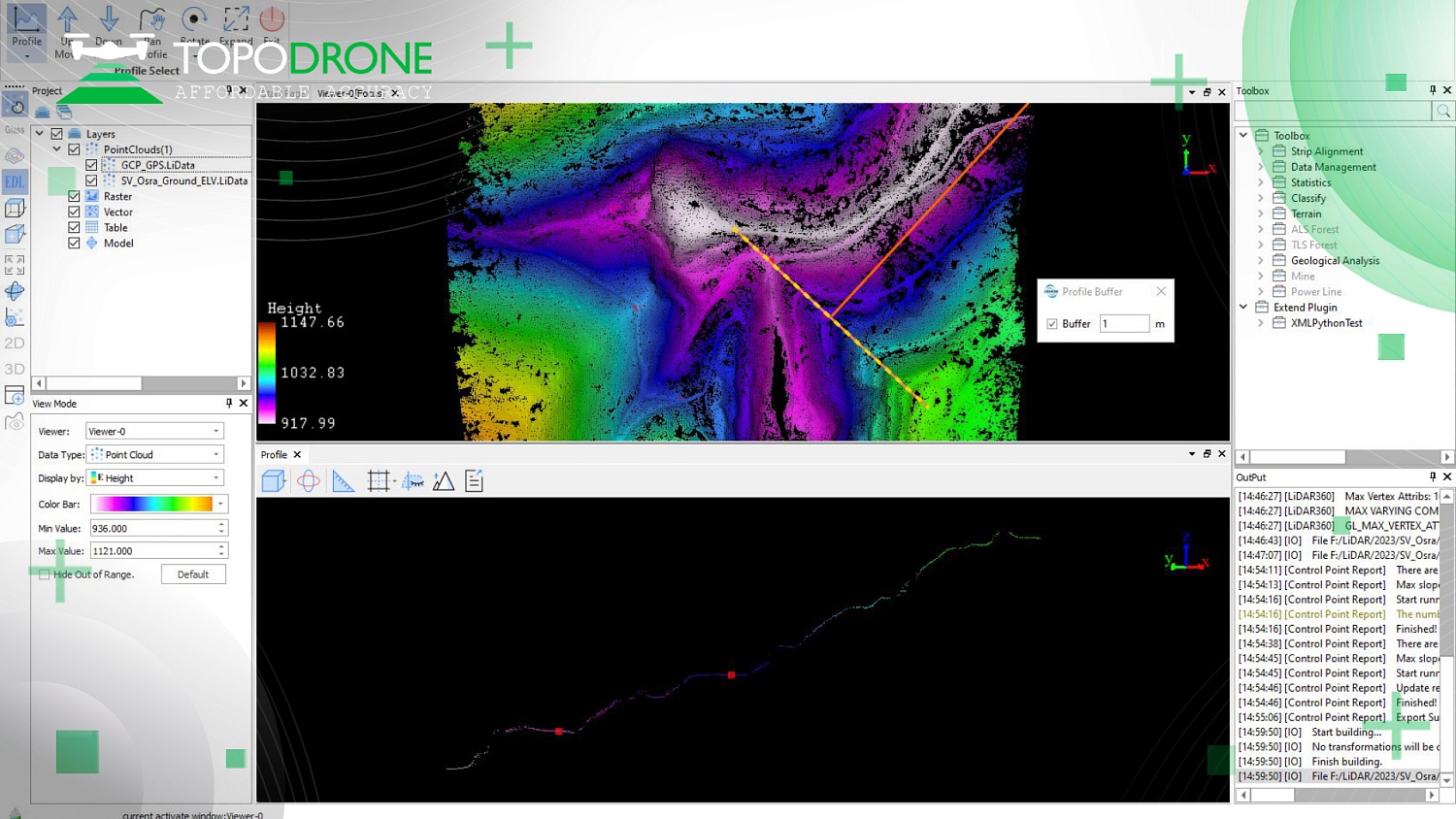

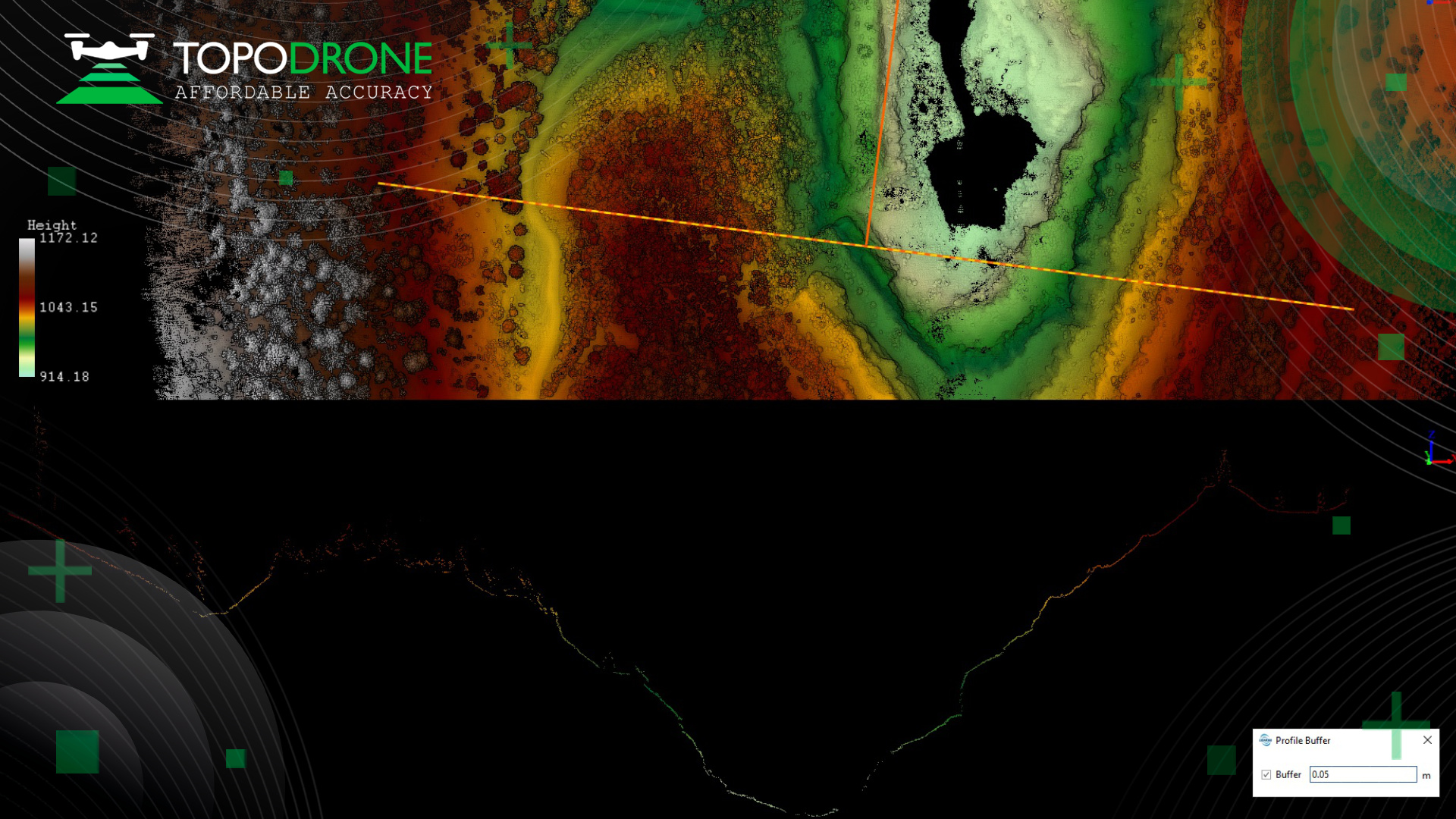

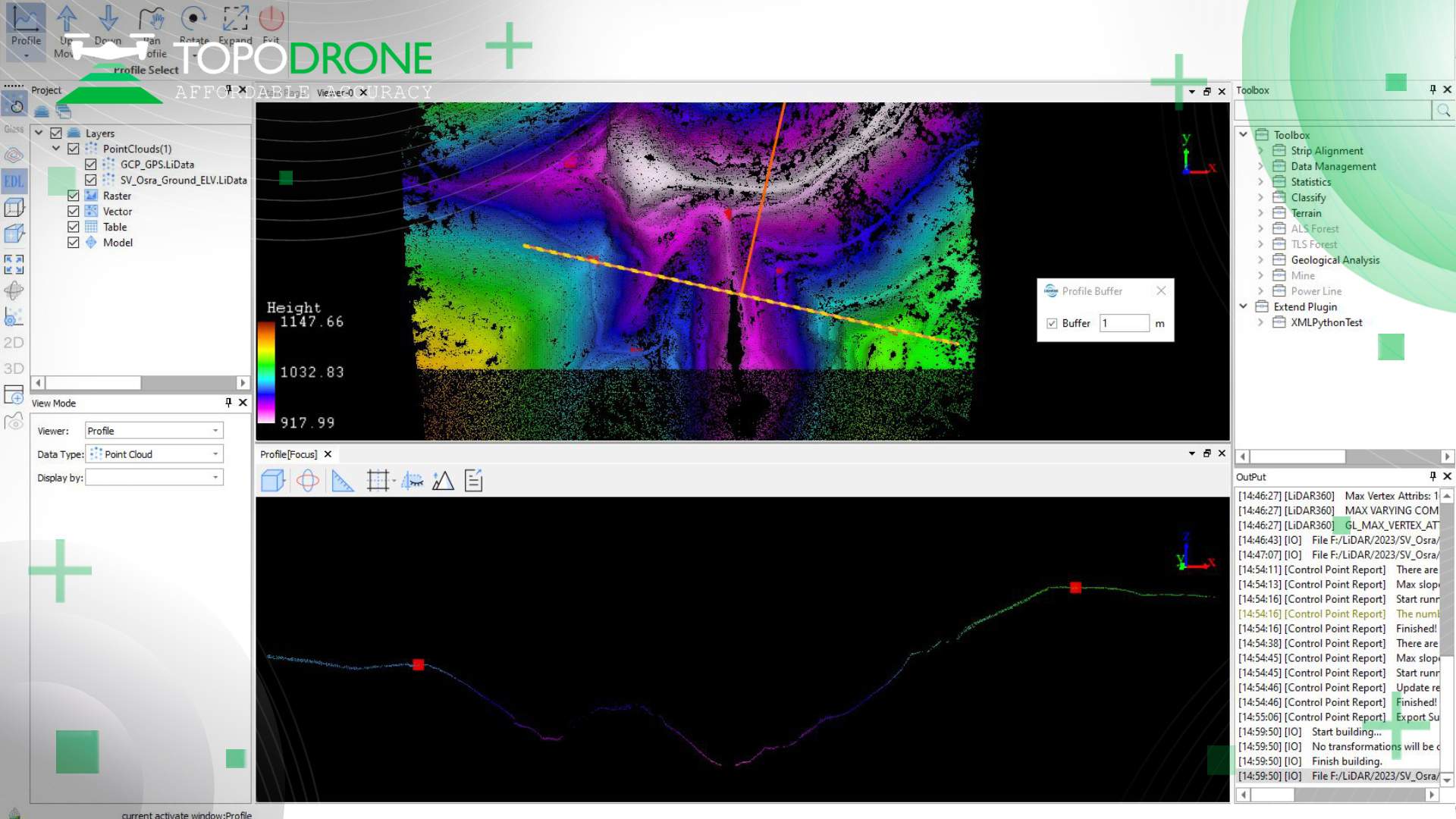

Fig. 17. Control points location on the terrain profile.

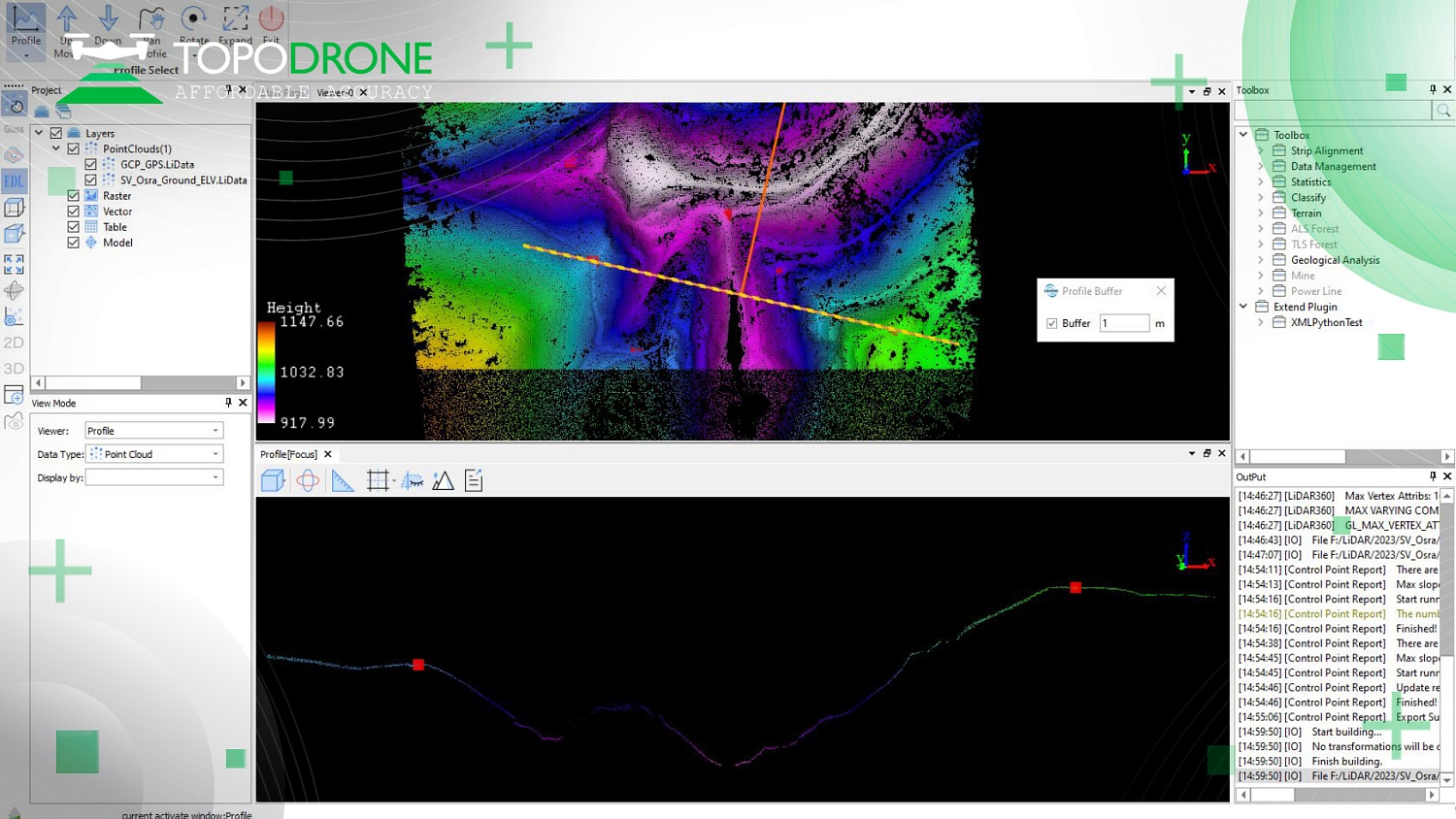

Fig. 18. Location of control points on the terrain profile.

Fig. 19. Location of control points on the terrain profile.

Advantages of using LiDAR:

The use of Light Detection and Ranging (LiDAR) technology for this project offers several advantages over traditional surveying methods. LiDAR, combined with the Topodrone LiDAR 200+ system, offers the following advantages:

Conclusion:

The Old Barite Quarry in Suceava county, Romania, is an interesting prospect for exploration and potential development. Simion Bruma, UAV pilot for BDS Topografie SRL, successfully completed a comprehensive survey of the quarry using the TOPODRONE LiDAR 200+ system.

The benefits of using LiDAR technology, including its accuracy, data density, efficiency and verification capabilities, make it an invaluable tool for analysing and understanding the geological features of the Old Barite Quarry. The combination of advanced LiDAR technology and UAV platforms opens up new possibilities for efficient and accurate exploration, ultimately supporting informed decision making for potential mining activities.

The Old Barite Quarry in Suceava county, Romania, offers a fascinating opportunity for exploration and analysis. This article describes the project, highlighting the involvement of Simion Bruma, a UAV pilot from BDS Topografie SRL, and the use of the latest model of the TOPODRONE LiDAR 200+, equipped with the Hesai XT32M2X sensor and a high-performance GNSS-based inertial navigation system. The project also included the collection of ground control points (GCPs) using GNSS technology to validate the data acquired with the LiDAR sensor.

Fig. 1. Simion Bruma, from BDS Topografie SRL.

Description of the area:

Fig. 2. Mountain forest area of The Old Barite Quarry, located in Suceava, Romania.

The Old Barite Quarry, situated in Suceava, Romania, provides a unique setting for investigation and potential development. The quarry covers an area of 100 hectares, including a mining area of 40 hectares. With altitudes ranging from a minimum of 914 meters to a maximum of 1172 meters, the region has significant elevation differences, adding to the geological significance of this site.

Field work, flights and altitude:

Fig. 3. TOPODRONE LiDAR 200+ installed on board the DJI M200 drone.

To effectively collect comprehensive data of the Old Barite Quarry, Simion Bruma carried out a single flight using the DJI M210 + TOPODRONE LiDAR 200+. The TOPODRONE LiDAR 200+ system, equipped with a high performance GNSS-based inertial navigation system, enabled the acquisition of up to 1,920,000 points per second with a 360° field of view and up to 3 cm x,y,z accuracy. The low weight of the LiDAR system (700 grams) provides a significant improvement in flight time and efficiency, even on board an old model DJI M200 drone.

Fig. 4. Mission planning with terrain following mode.

The flight was conducted at an altitude of 120 meters above ground level (AGL) to ensure optimal coverage of the quarry. To maintain consistent overlap and ensure quality data acquisition, an 80% frontal overlap and 58% lateral overlap was maintained throughout the flight. The UAV was programmed to maintain a speed of 9.6 meters per second while incorporating terrain awareness, which helped the aircraft maintain a consistent distance from the ground, ensuring consistent overlap during data acquisition.

Data processing:

It is critical that all steps of data processing were done in the field to evaluate the quality of the data, since the area is far from the BDS Topografie SRL office and it would not be necessary to spend time to return to the site if something went wrong.

First, Semion post-processed the flight trajectories using TOPODRONE Post Processing software and then generated an accurate point cloud in the Romanian coordinate system.

After that, an automatic classification of the point cloud was performed to obtain a real terrain level. We would like to draw your attention to the high density of the point cloud and the triple return, which allowed to obtain accurate and detailed terrain structure even in dense forest area.

Fig. 5. LiDAR data processing in the TOPODRONE Post Processing software.

Fig. 6. LiDAR data processing in the TOPODRONE Post Processing software.

Fig. 7. LiDAR data processing in the TOPODRONE Post Processing software.

Fig. 8. LiDAR point cloud over the mining site area.

Fig. 9. LiDAR point cloud over the mining site area.

Fig. 10. LiDAR point cloud over the mining site area.

Fig. 11. Terrain model reconstructed from classified LiDAR data.

Fig. 12. Terrain model reconstructed from classified LiDAR data.

Fig. 13. Terrain model reconstructed from classified LiDAR data.

Fig. 14. Terrain model reconstructed from classified LiDAR data.

Fig. 15. Terrain model reconstructed from classified LiDAR data.

Verification of LiDAR data:

To ensure the accuracy and reliability of the collected LiDAR data, seven ground control points (GCP) were measured using GNSS technology. These GCPs were used as control points for the elevation measurements. The difference in elevation between the GCP points ranged from 0.002 meters to -0.053 meters, demonstrating the high accuracy of the LiDAR data collected by the TOPODRONE LiDAR 200+ system.

Fig. 16. Control points location and automatic accuracy report.

Fig. 17. Control points location on the terrain profile.

Fig. 18. Location of control points on the terrain profile.

Fig. 19. Location of control points on the terrain profile.

Advantages of using LiDAR:

The use of Light Detection and Ranging (LiDAR) technology for this project offers several advantages over traditional surveying methods. LiDAR, combined with the Topodrone LiDAR 200+ system, offers the following advantages:

- Accuracy and precision: The TOPODRONE LiDAR 200+ system, equipped with the Hesai XT32M2X sensor, captures up to 1,920,000 points per second, ensuring accurate and precise measurements. This enables the creation of detailed and reliable topographic maps of the quarry, helping to identify key geological features and potential mining areas.

- Data density and detail: The high data acquisition rate of the TOPODRONE LiDAR 200+ system results in a dense point cloud, providing a wealth of data for detailed analysis, facilitating a thorough examination of the quarry morphology and supporting geological and structural analysis.

- Efficient data acquisition: LiDAR technology combined with UAV platforms allows for fast and efficient data collection. The TOPODRONE LiDAR 200+ system's ability to quickly acquire large volumes of data ensures timely completion of the survey. This airborne approach significantly reduces the time and resources required compared to traditional ground-based methods.

- Verification and accuracy assurance: The integration of GNSS technology in the calculation and generation of the LiDAR trajectory, as well as in the measurement of the ground control points (GCP), ensures the accuracy and reliability of the collected LiDAR data. The small height differences observed between the GCP's highlight the high accuracy of the TOPODRONE LiDAR 200+ system.

Conclusion:

The Old Barite Quarry in Suceava county, Romania, is an interesting prospect for exploration and potential development. Simion Bruma, UAV pilot for BDS Topografie SRL, successfully completed a comprehensive survey of the quarry using the TOPODRONE LiDAR 200+ system.

The benefits of using LiDAR technology, including its accuracy, data density, efficiency and verification capabilities, make it an invaluable tool for analysing and understanding the geological features of the Old Barite Quarry. The combination of advanced LiDAR technology and UAV platforms opens up new possibilities for efficient and accurate exploration, ultimately supporting informed decision making for potential mining activities.

Products

All

3

LiDAR Systems

1

TOPODRONE

1

.png)